- Your current location: Home >> Product >> Casting sand treatment equipment

Casting sand treatment equipment

- Foundry molding machine Casting sand treatment equipment Accessory description Automatic modeling of sand molds Pig iron castings Qualification certificate

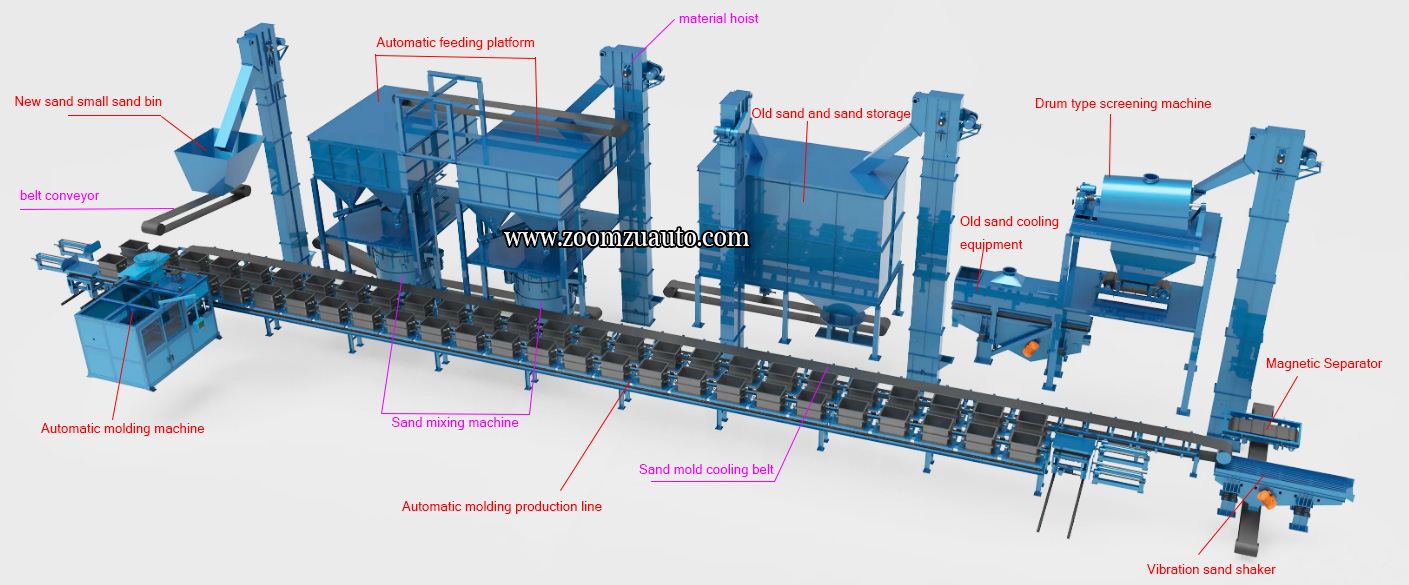

The function of the wet sand treatment system is to provide the casting sand that can be used for molding for the casting molding machine. When the poured sand mold separates the casting from the casting sand through the vibration machine tool, the old casting sand is then re-entered into the sand treatment system, and becomes loose casting sand after being processed by the crushing equipment, screening equipment and dust removal and cooling equipment. Finally, the sand is stored in the designated container for static cooling. When the casting molding machine is running for production, the old sand will be mixed again with new sand, bentonite, coal powder, water and other materials through the sand mixer. The mixed sand can meet the conditions of casting sand and then be transported by belt to the casting molding machine for use. Tidal sand treatment system needs to design appropriate treatment capacity according to the sand demand of molding machine and production line.

- Explore specific introductions

-

1. Vibration crushing of sand molds, casting and sand separation2. High temperature cast old sand magnetic iron blocks are transported by belt to a certain height and position3. Rolling screening of old sand to remove impurities and some iron blocks4. After cooling the old sand, remove the dust from the old sand through vacuum equipment5. After lifting the old sand, perform a second fine screening of the old sand6. Store old sand in a specific sand bin to cool down and wait for reuse7. Adding new casting sand to the old sand and mixing it with materials to obtain casting sand8. Transport the new casting sand to the molding machine

- Click to enter >>

-

01.

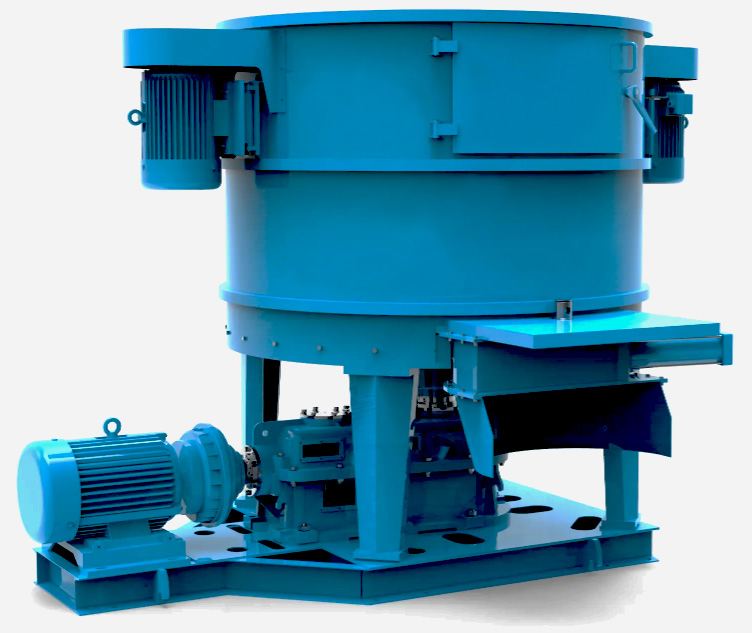

GS High-speed rotor sand mixer

This equipment is mainly used for mixing and mixing molding sand in the casting workshop. It can not only mix single casting sand for casting molding machines, but also dry sand, self-hardening sand, surface sand and back sand. It can also be used for mixing various powder and granular materials in glass, ceramics, refractories and other industries;

1) The lining plate of the sand mixer is made of high-strength wear-resistant plate, which completely solves the problem of sand sticking on the bottom plate of the machine basin, significantly improves the quality of molding sand and maximizes the service life of the scraper;

2) The double "S" type scraper is the best match with the high-speed rake rotor, with large sand mixing capacity, strong mixing ability and good molding sand performance;

3) The newly designed side discharge door is flexible in opening, stable and reliable in operation and fast in discharging;

4) The steel structure base makes the transportation and installation of the machine very convenient;

Reading >>

- 02.

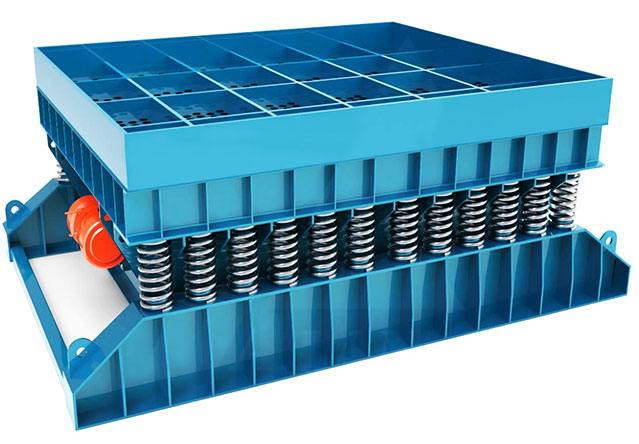

Boiling cooling equipment for used foundry sand

The modified equipment is used for the transportation, cooling, and dust removal of old sand (hot casting sand) used for self hardening sand and clay sand recycling in the casting workshop. It is an ideal heat exchange and cooling cooling device.

1) The vibrating boiling cooling bed is composed of the bed body of the perforated fish-scale plate and the air blowing system;

2) The blast system blows cold air from the lower part of the fish-scale plate to make the hot sand in boiling state. The air fully contacts with the hot sand to take away the moisture in the hot sand and discharge it by the dust removal system. The hot sand achieves the purpose of cooling and reduces part of the dust after pouring combustion. The cooled old casting sand is continuously transported to the sand outlet for the next treatment stage;

3) The heat exchange between sand and air in boiling state is 6-10 times greater than that in static state;

Reading >>

- 03.

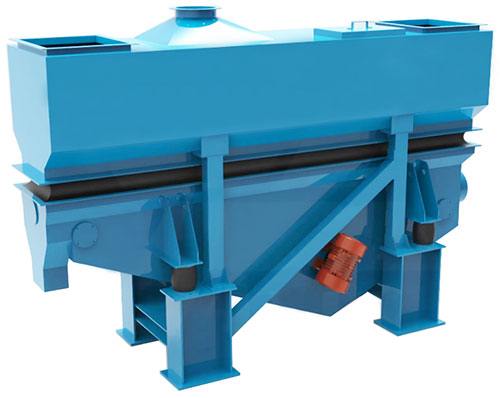

Rolling crushing and screening equipment

This equipment is used for preliminary screening of cast sand, secondary crushing of smaller old sand blocks, and dust removal and cooling. The built-in hexagonal cylindrical screen of the equipment has a certain inclination angle. Through continuous rolling of the cylindrical screen, the old sand blocks are crushed, and the old sand in powder state enters the next processing process. The hardened sand blocks, coated sand cores, and small iron blocks that cannot be broken will fall off and be collected in waste bags due to their tilted state. The dust generated during rolling screening will be removed by installing ventilation and dust removal equipment to reduce the sand temperature of the old sand.

1) Stable operation, reliable operation and fine screening;

2) The long mesh is cold-drawn stainless steel high-strength thick and fine woven mesh, with long service life;

3) he screen is fixed by pulling and pressing. The screen surface is tight, not easy to be damaged, has good rebound and crushing effect, and is easy to replace;

4) t can effectively ventilate, remove micro-powder, reduce mud content and achieve certain cooling effect;

Reading >>

- 04.

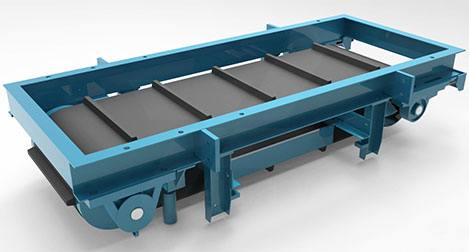

Conveyor type vibrating shakeout machine

This series of sand removal equipment separates the sand mold from the casting through vibration. Internally, the vibrating mesh size and shape are designed based on the volume, size, and external structure of the casting. After entering the modified equipment, the casting gradually separates from the old sand during the vibration process, which falls into the belt through the mesh, and the casting and large pieces of scrap iron material will be screened out. The vibration sand removal equipment is the first step of the old sand treatment system and the boundary between the molding department and the sand treatment department. It is used for the sand removal of high-temperature sand molds on the molding line and the transportation of castings.

1) High productivity, low use cost, wide applicability, simple structure, convenient installation and maintenance;

2) It is convenient to install closed dust removal equipment and make noise isolation;

Reading >>

- 05.

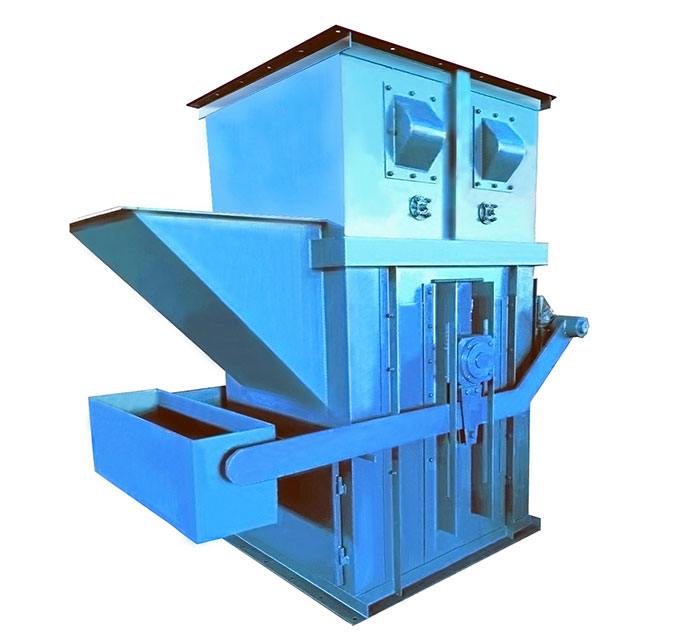

Material bucket lifting device

This equipment is a commonly used vertical conveying equipment in mechanized casting workshops, which lifts and transports the bottom material to a specific high position, saving space in the workshop. It is mainly used to lift old sand, waste sand, new sand, clean iron shot and other loose materials;

1) This machine has a large conveying capacity, high lifting height, stable and reliable operation, and long service life;

2) This machine, in conjunction with belt conveyors and other equipment, can be arranged into various forms of conveying systems;

Reading >>

- 06.

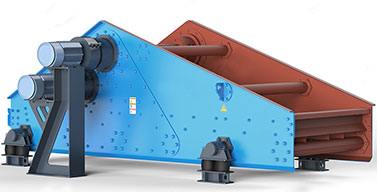

Inertia linear vibration fine screening machine

This series of equipment is a new type of efficient screening equipment, mainly used for fine screening of new or old sand in casting workshops, and can also be used for screening other granular and dispersed materials.

1. This feature is excited by two vibration motors, causing the screen body to vibrate in a straight line, and the material is continuously thrown up and screened.

2. There are three types of discharge methods for the waste chute: front discharge, rear discharge, and right discharge.

Reading >>

- 07.

Suspended advanced magnetic separator

This device is widely used in industries such as metallurgy, mining, and casting. It is used in casting production to adsorb and screen iron blocks doped in old cast sand after pouring, effectively separating magnetic metal objects from the sand layer. The device is designed and installed above the conveyor belt, with an independent support structure suspended by high-strength magnetic magnets and the distance between the magnets and the conveyor belt can be adjusted to control the size of the adsorption force.

1. This machine adopts high-strength magnetic materials, which have the characteristics of strong magnetism, good magnetic separation effect, stable operation, and reliable performance.

2. The magnetic system has slow aging and long lifespan, with a decrease of only 18% in 5-7 years, still close to electromagnetic separation equipment.

3. When the magnetic field decreases, the magnetic system can be removed for magnetization, achieving cyclic use.

Reading >>

- 08.

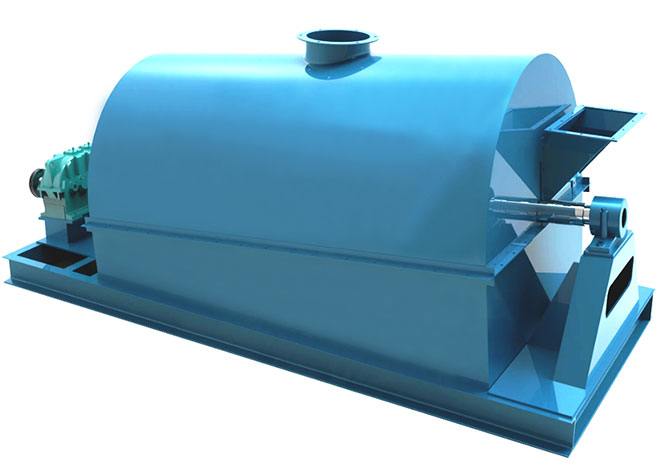

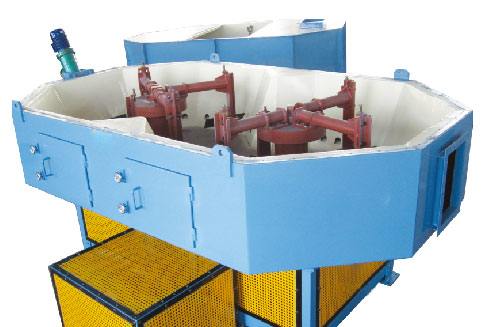

Double rotary mixing and cooling equipment

This equipment is mainly suitable for cooling clay sand and old sand. Fully stir and mix the old sand to ensure uniform temperature, humidity, and composition. While cooling, complete the pre mixing process to prepare high-quality molding sand.

1. The equipment has a compact structure, smooth operation, low noise, and low energy consumption; The reverse rotating crosshead drives the scraper to push the material to mix evenly; High pressure air blowing keeps the old sand in a boiling state, achieving cooling effect; The opening of the discharge door can be adjusted to control the emptying of materials in the machine basin;

2. It can be combined with the old sand humidification cooling system, blower, and exhaust fan to form an old sand cooling unit, with good cooling effect

Reading >>

- 09.

Drum type sand removal equipment

This equipment is mainly used for sand removal treatment of the cooled sand mold after pouring at the tail of the molding line, as well as cleaning and cooling of the castings. This equipment is composed of a front drum body, an initial sand removal section, a rear drum body, and a final sand removal section. When the sand mold and casting fall into the drum, the drum continuously rotates to cause the sand mold to repeatedly roll and collide, achieving the effect of separating the old sand and casting. The scattered old sand falls into the conveyor belt through the holes, and the casting that stays inside the equipment will gradually move towards the final sand removal end (tail) as the drum rolls.

Reading >>

- 10.

Casting sand dust removal equipment

The dust laden gas is sucked into the dust collector through the induced draft fan, and filtered by the filter bag. The dust is trapped on the outer surface of the filter bag, while the clean gas is discharged through the inside of the filter bag. When the dust accumulation on the outer surface of the filter bag reaches a certain level, the control system will issue a command to open the pulse valve and blow compressed air into the inside of the filter bag, causing the filter bag to instantly expand and vibrate, thereby shaking off the dust attached to the outer surface of the filter bag into the ash hopper, achieving the purpose of cleaning the dust.

Reading >>

- 11.

Automated electrical control system

The dust laden gas is sucked into the dust collector through the induced draft fan, and filtered by the filter bag. The dust is trapped on the outer surface of the filter bag, while the clean gas is discharged through the inside of the filter bag. When the dust accumulation on the outer surface of the filter bag reaches a certain level, the control system will issue a command to open the pulse valve and blow compressed air into the inside of the filter bag, causing the filter bag to instantly expand and vibrate, thereby shaking off the dust attached to the outer surface of the filter bag into the ash hopper, achieving the purpose of cleaning the dust.

Reading >>