Research and development of conventional horizontal parting automated casting molding machine:

In March 2013, based on the analysis of casting development trends and visits to Chinese casting enterprises, combined with international casting equipment design concepts, we developed and designed the first horizontal parting fully automatic casting and shaping machine with high cost-effectiveness suitable for tidal sand casting and shaping. After two months of optimization and improvement, we began mass production of a conventional single shot sand cylinder horizontal shot sand automatic shaping machine with a sand box size of 420mm-710mm in May.

In June 2014, after more than a year of sales to some casting enterprises in China, according to the production needs of some casting enterprises for casting size, the design of the sand box size of the automated casting molding machine was increased in the original horizontal shot sand automatic molding machine production technology. The sand box size of the casting molding machine was expanded to 750mm-850mm and began to be sold and well applied;

Establishment of equipment installation and maintenance technology section:

In November 2014, our casting molding equipment was sold to six regions in China where casting enterprises are relatively concentrated. A total of 32 sets of equipment were installed and put into use. In order to meet the production needs of these casting enterprises and provide after-sales service for the equipment, we officially established the equipment installation and maintenance and repair section, providing timely service and related supporting equipment support when enterprise users need our help;

Establishment of Automation Tidal Sand Treatment Equipment Branch:

In May 2015, we recruited technical talents from South China University of Technology and established the Electrical Automation Technology Department to design and manufacture horizontal parting automated pouring lines with independent intellectual property rights; In August of the same year, we began to collaborate with Qingdao Second Casting Machinery Group to develop and produce automatic processing equipment for tidal sand. In November, we established a second branch in Qingdao, China to begin mass production of tidal sand processing equipment, providing casting enterprises with automated pouring lines and tidal sand automatic processing systems;

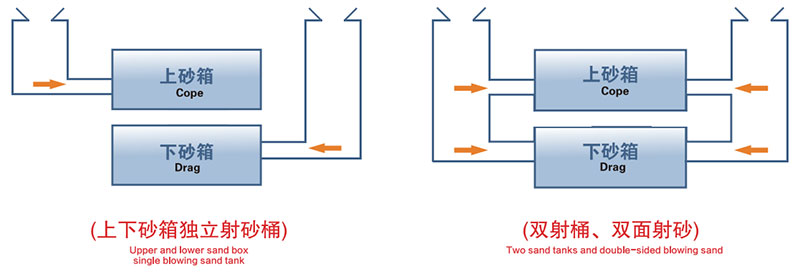

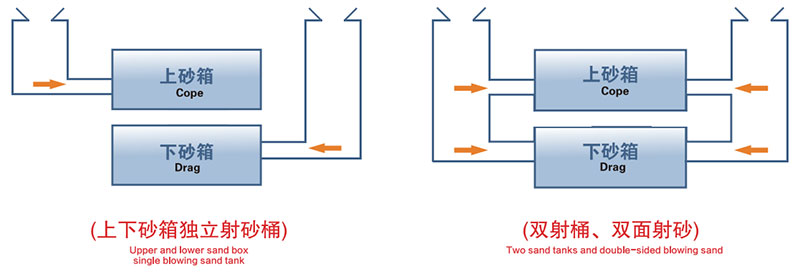

Research and development of double-sided sandblasting horizontal parting automatic casting molding machine:

In February 2016, we made adjustments to the automated casting molding machine with a conventional single shot cylinder horizontal sand box size of 750mm-850mm. After a year and a half of user feedback, it was found that the problem was that it could not achieve good sand shooting effect and pre compaction of sand molds for complex and high height molds. Based on this feedback, we adopted separate sandblasting cylinders for the upper and lower sandboxes, allowing them to separate and shoot sand independently, thereby improving the flow rate of sand carried by the air pressure during sandblasting. The modified effect has greatly improved, but there are still a small number of sandblasting shadows. It was not until May of the same year that we redesigned the sandblasting method, allowing the upper and lower sandboxes to shoot sand horizontally from both sides and increasing the exhaust of the sandbox, that we were able to solve the problem of sandblasting shadows caused by large mold size, high height, and many dead angles. The automatic casting molding machine for this sandblasting method is the double barrel side sandblasting horizontal parting automatic casting molding machine;

Research and development of automatic casting and molding machine for horizontal parting of large-sized sand boxes:

In April 2017, after long-term cooperation with casting enterprises, according to user feedback, many casting products with larger sizes cannot be fully covered by automated casting molding machines with conventional sand box sizes. Therefore, we still need to retain a portion of molding workers for the casting molding of large-sized casting products. Therefore, we need to produce automated casting molding equipment with larger sand boxes. Starting from May of the same year, design and reasoning were carried out to analyze possible sand shooting problems and the possibility of sand mold cracking caused by oversized and horizontal sand molds. Finally, it was decided to make adjustments and avoid possible problems based on the structure of double-sided sand shooting. In July 2017, 5 large-sized double-sided sand shooting horizontal parting automated casting molding machines were customized and assembled according to the needs of 5 cooperating users. Among them, 3 casting users were equipped with automated pouring lines. This batch of equipment was gradually put into casting production in October 2017 and received good feedback;

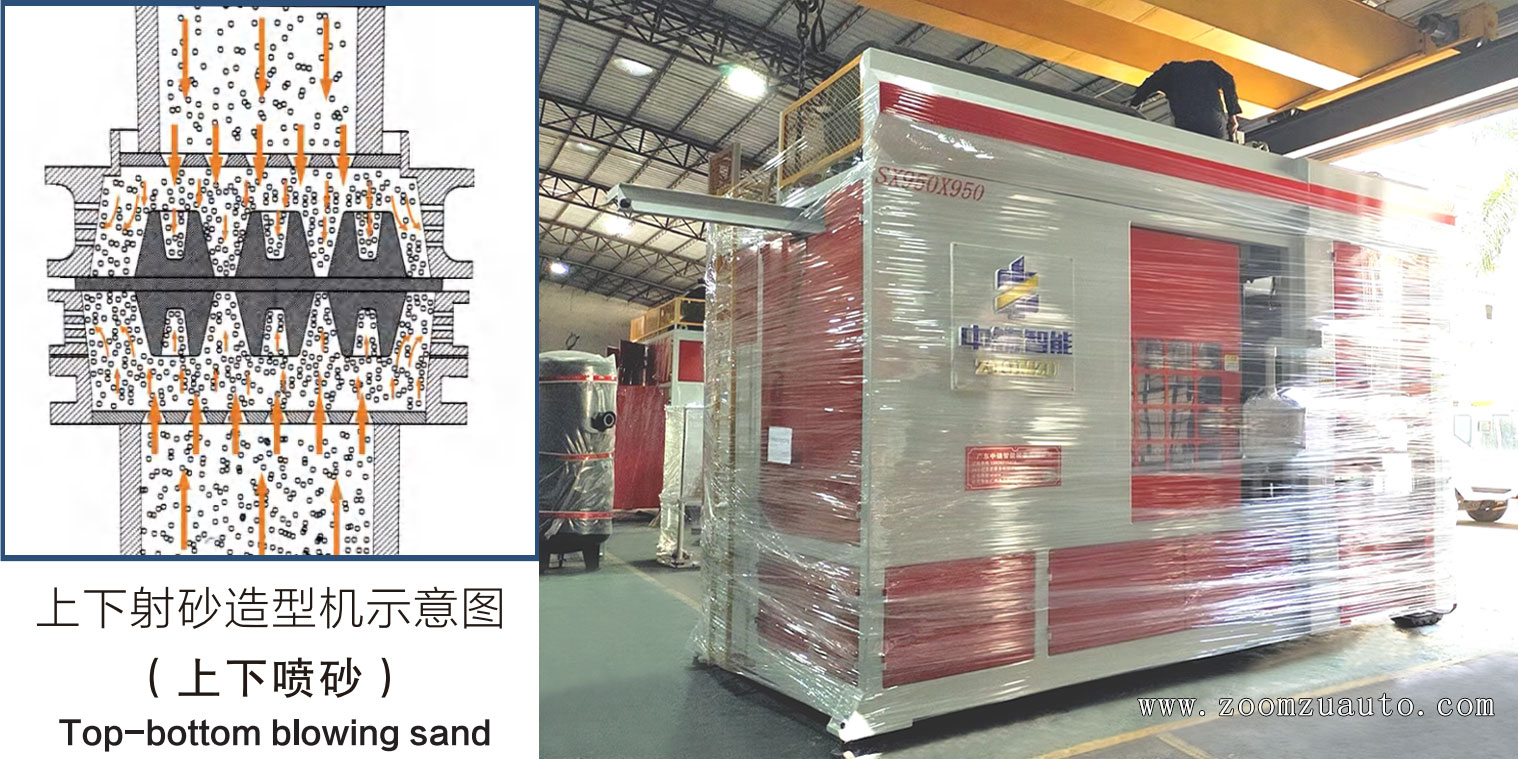

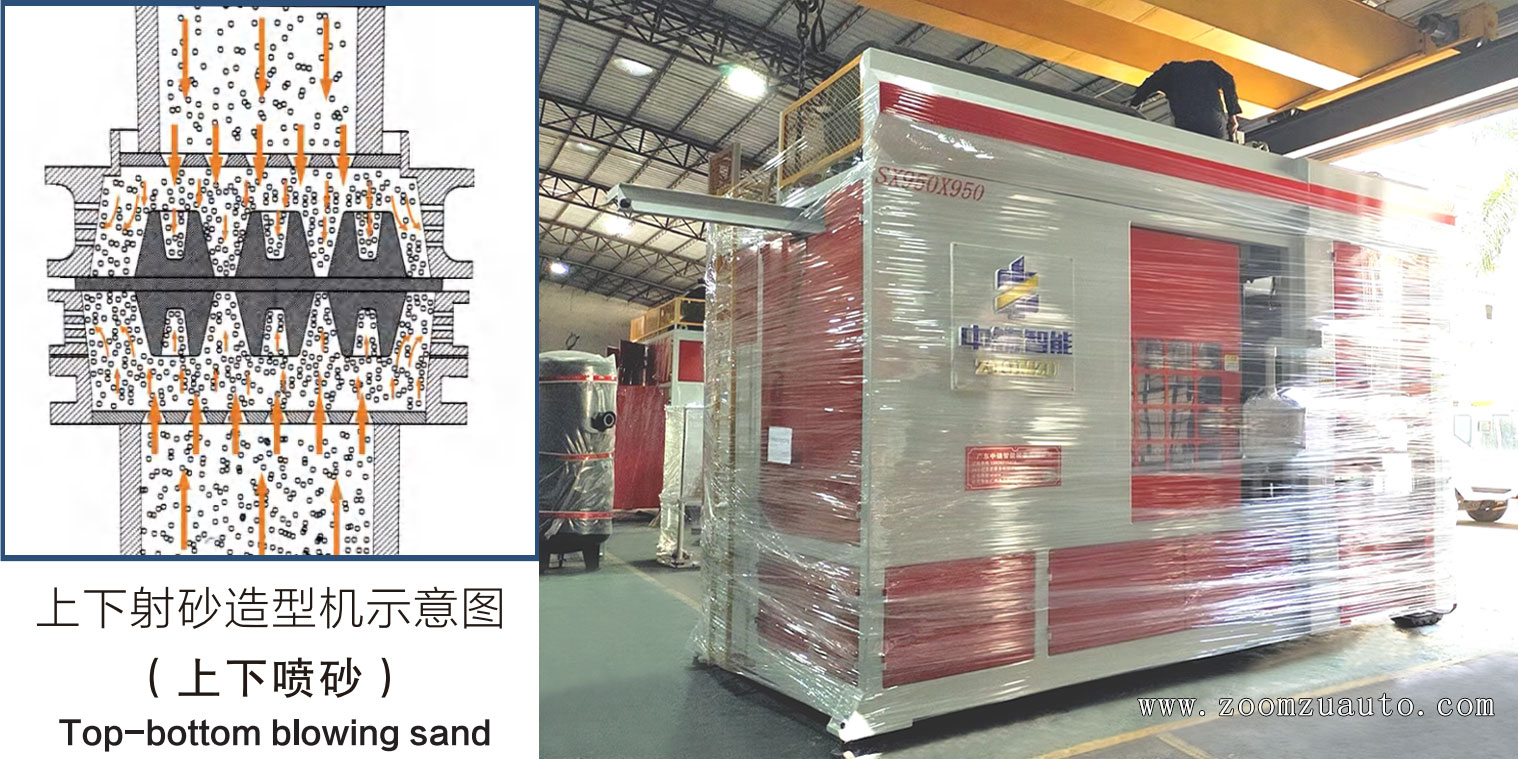

Research and development of automatic casting molding machine for top and bottom sand shooting horizontal parting:

In February 2018, we conducted a more detailed analysis of the structural design advantages of the double barrel side sand shooting horizontal parting automatic casting molding machine. We began to redesign and produce an automated molding equipment that can be more practical, meet the needs of the majority of casting products to the greatest extent possible, and be suitable for the sand mold size range of 500mm-950mm. We mainly optimized the operating space of the molding area, increased compaction and compaction, and upgraded the hydraulic device to have the best sand shooting pre compaction method - top and bottom sand shooting. In April of the same year, we completed the automatic casting molding machine for independent sand shooting horizontal parting at the top and bottom, and made an appearance and promotion at the China Foundry Exhibition in May 2018;

Design and selection of sliding out function for the lower sand box:

In March 2019, based on feedback from a small number of casting enterprises, we upgraded all types of automated casting molding machines. The lower sand box of the automated casting molding machine was changed to a sliding and retracting state on the original drawing, and can be selected according to the casting needs of users. The sliding out of the lower sand box is mainly convenient for a small number of users to complete the process more easily and accurately when placing larger coated sand cores inside the sand mold cavity;