-

-

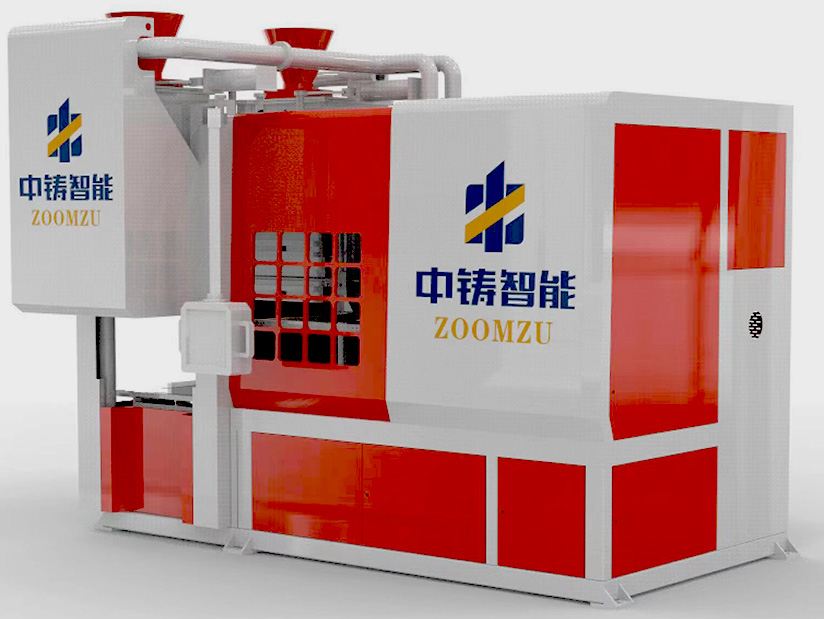

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

A large-scale horizontal parting green sand molding machine developed according to the automation molding needs of casting enterprises for large-sized castings. It adopts a design of two sandblasting cylinders simultaneously sandblasting the front and rear sides of the sand box, which can reduce the gas pressure of sandblasting and smoothly fill the sand box with sand molds, making it easy to complete sandblasting and achieve the desired effect in a specific short time during the molding process.

1) This machine can customize specific sand box sizes according to specific needs;

2) Two sand cylinders are used for horizontal sandblasting;

3) The size of the sand box is within the range of 1000mm-1600mm;

4) The height of the sand mold is 250mm-500mm (adjustable height);

5) Suitable for castings with a height range of 180mm and a relatively simple structure;

6) The molding speed of sand molds larger than 1000mm is 30-40 sand molds per hour;

In the field of casting, a large proportion of casting companies produce castings with larger sizes, or require a certain amount of molten iron to be poured within a specific production time to improve efficiency and save casting production costs in order to replace other casting processes (such as resin sand casting). Therefore, the requirements for the size of the sand box of automated molding machines are also higher. The horizontal parting green sand molding machine with double-sided sandblasting on both sides is developed and manufactured according to this demand. The size range of the sand box is about 750mm-1600mm, and it adopts a structural design of two sandblasting cylinders simultaneously sandblasting from both sides. The purpose is to fully and uniformly fill the casting sand inside the sand box when the sand box size is large, which causes a long sandblasting stroke distance. The side sandblasting method can also avoid the influence of gravity on the casting sand to the greatest extent. Therefore, under a certain pressure, the gas can carry a larger flow rate of sand, which meets the demand for casting sand in larger sand boxes during sandblasting;

As of November 2023, we have provided 86 large-sized green sand molding machines with double-sided sandblasting on both sides for China and even internationally. The maximum size of the sand box can reach 1620mm. In Guangdong and Shandong provinces of China, two large-sized sand box double-sided sandblasting horizontal parting automatic molding machines with dimensions of 1620mm x 1400mm have been put into operation in casting enterprises and have been widely used and recognized by users in casting production; This is also the progress we have made by daring to try and break through;

3. In previous usage cases, this model has mostly been produced using green sand casting for large-sized castings such as cast iron manhole covers, manhole rings, grates, fireplaces, fire hydrants, counterweight iron, and park patterned iron art;