-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

The common automated casting and molding production lines for tidal sand (clay sand) mainly include vertical parting box less injection molding line, horizontal parting box less injection molding line, and multi contact static pressure box molding line. In the past decade of rapid development and widespread application, machine automatic molding technology, automated pouring, and automated sand mixing and sand making technology have become very mature. Currently, most casting molding lines work on the principle of using pneumatic sand addition and hydraulic compaction to achieve automatic molding of sand molds.

click : 416

The chemical composition of ductile iron castings must be strictly controlled, otherwise it is difficult to meet customer requirements. Strictly control the process from the selection of raw materials, formulation of smelting process, temperature control, and pre furnace spheroidization incubation treatment. Below, we will summarize and introduce the key points of ductile iron smelting and spheroidization treatment!

click : 412

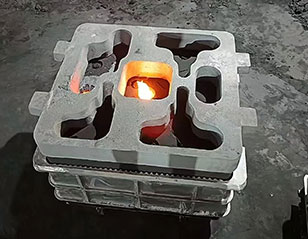

The main material used is aluminum or ductile iron (QT) material, which is cast and formed. The frame sleeve is finely processed into serrated and inclined concave and convex patterns using a milling cutter, ensuring that the sleeve box and sand mold can be accurately and tightly fitted. At the same time, it is beneficial for the sand mold to dissipate heat and exhaust around the cavity during the pouring process.

click : 484

Below is a brief analysis of the identification methods for ductile iron castings and gray iron castings for everyone

click : 380