Sand casting molding equipment

- Foundry molding machine Casting sand treatment equipment Accessory description Automatic modeling of sand molds Pig iron castings Qualification certificate

- 01.

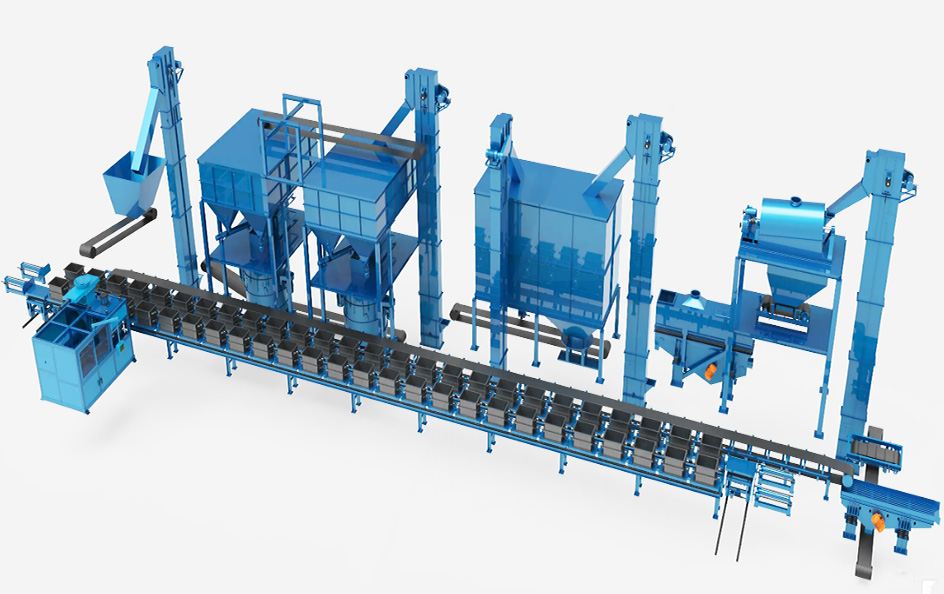

Automatic casting molding equipment

-

Conventional casting molding machines are suitable for producing small batches and relatively complex castings. The molding speed during normal operation is 80-100 sand models per hour. When it is necessary to place laminated sand cores, the molding speed is 30-70 sand molds per hour. The production mode is more diversified, and can be flexibly selected according to production needs and workshop space.

-

- 02.

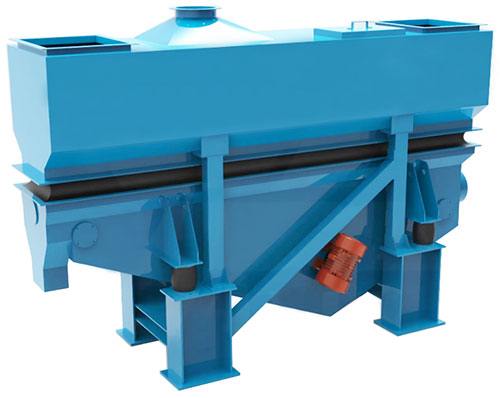

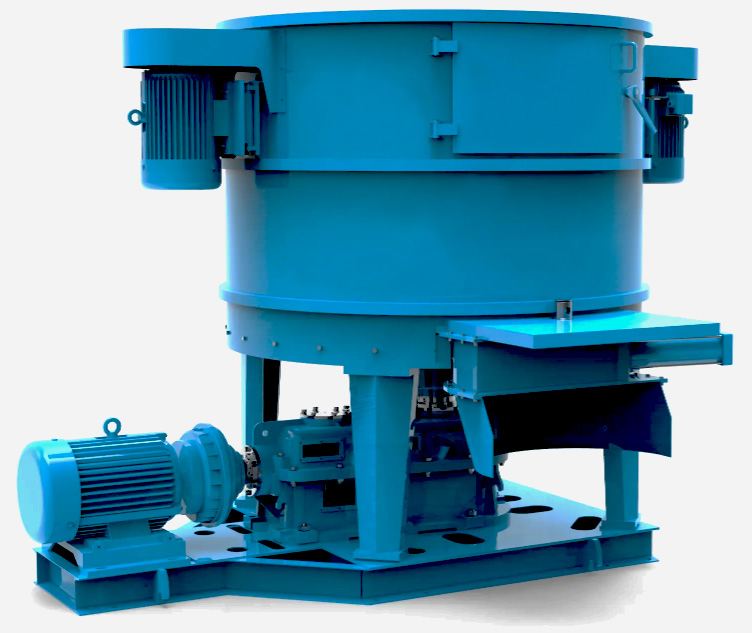

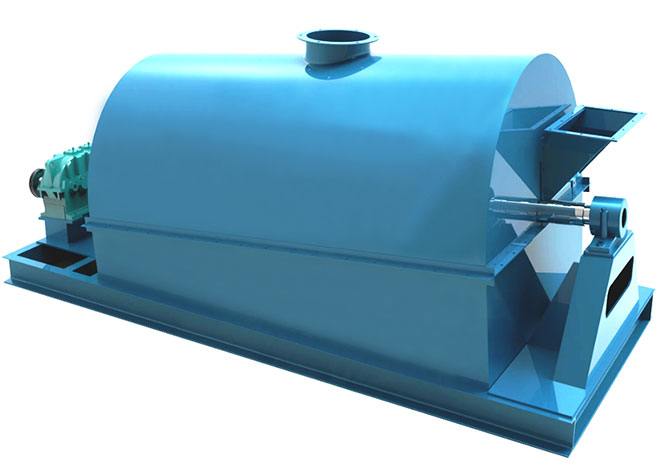

Casting sand processing equipment

-

The function of the casting sand processing system is to provide casting sand that can be used for forming for the casting molding machine. When the poured sand mold is separated from the casting sand by a vibration machine, the old casting sand will re-enter the processing system of the casting sand, and then undergo systematic treatment by crushing equipment, screening equipment, and dust removal and cooling equipment to become loose casting sand. The processed molding sand is stored in designated containers for static cooling. When the casting machine is running for production, the old casting sand, new raw sand, bentonite, and coal powder will be mixed with water again to form new casting sand, which is finally transported to the casting machine through a belt conveyor. The casting sand processing system needs to be designed with appropriate processing and mixing capabilities based on the hourly sand demand of the molding machine and production line.

-

-

-

-