-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

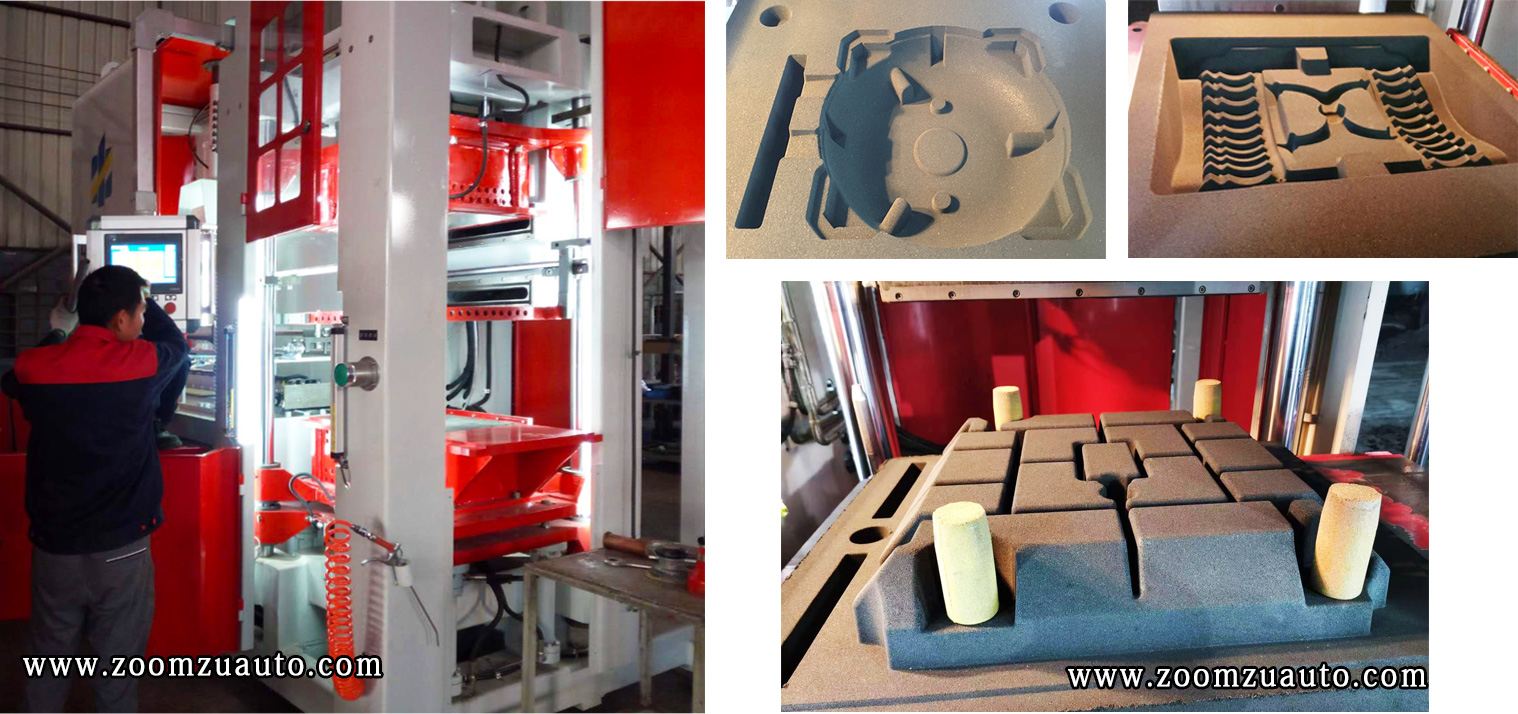

This is a commonly used automated casting molding machine in the field of wet sand casting, and it was also developed early to replace manual sand turning molding and semi-automatic molding machines. The efficiency of its molding is 5-8 times that of manual molding. The use of automated casting molding machines not only reduces the production cost of castings, but also ensures that the quality error and yield of castings remain at a certain stable standard. This equipment is suitable for automatic molding production of small and medium-sized castings with relatively simple volume and shape, which can improve the working environment of the workshop and reduce the workload of workers.

1) This type of machine can customize specific sand box sizes according to specific needs;

2) Use # 46 anti wear hydraulic oil;

3) Double sided steel or aluminum molds are required;

4) Fully automatic one button intelligent continuous or single cycle operation molding, automatic fault detection and alarm, emergency locking and safety warning;

5) Language switching can be selected according to regional needs;

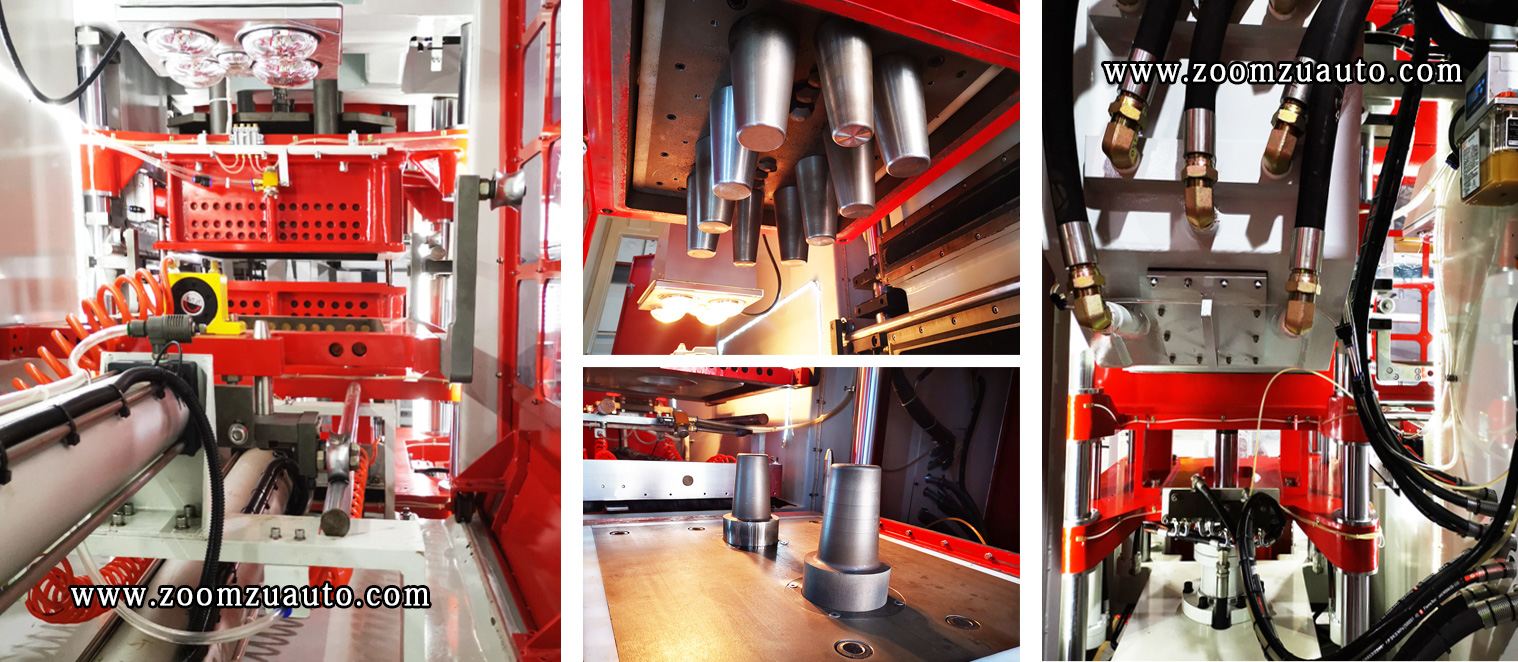

6) Hydraulic compaction through air pressure and sand addition;

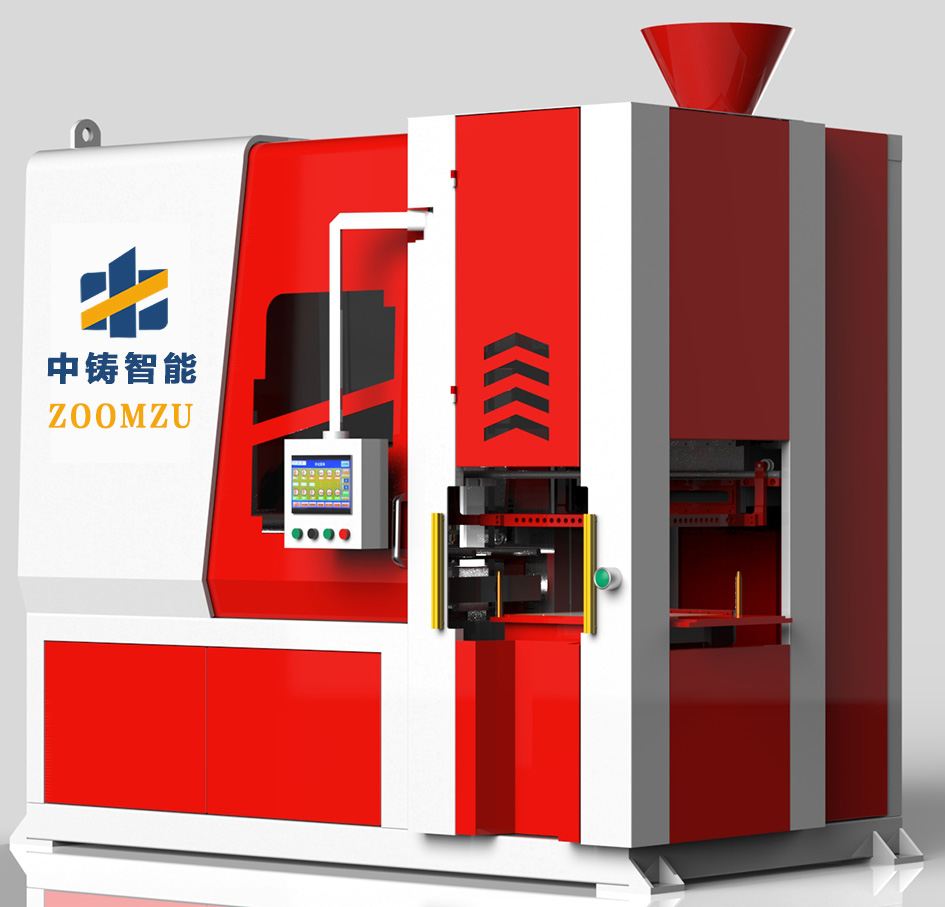

This model of automated casting molding machine adopts a structural design of separate sand injection cylinder side sand injection. It was developed in 2013 and widely used in the production of automatic molding by casting enterprises. It is also the earliest and most common automated casting molding machine in all the fields of wet mold sand casting in China. The sand box size is in the range of 400mm-750mm, the structure is relatively simple and the technology is mature, so the price is relatively affordable compared to other models of casting molding machines.

This casting molding machine is suitable for wet mold sand molding with relatively simple appearance structure of casting products. It uses gas pressure to inject sand from the side to fill the sand box, and then compacts the inside of the sand box through a hydraulic cylinder to complete the automatic molding of the sand mold. In general, we will analyze and judge based on the overall casting characteristics and requirements of the casting enterprise. Only when we ensure that the casting molding machine can be competent and meet the requirements of casting production in casting molding, will we recommend it to the user group. Moreover, the supporting molds of this equipment also have high technical requirements in development and production;

In more than 10 years of technological innovation, we have also upgraded and installed a hydraulic cylinder contact secondary compaction device on this model of molding machine for casting enterprises with a single type of casting. That is, after the airflow fills and compacts the sand box with sand, a small oil cylinder contact is used to perform a second compaction on a specific point of the sand mold, in order to improve the compactness of the sand mold and compensate for the uneven sand injection problem faced by this model of molding machine in difficult mold molding;

The electrical components and hydraulic devices of this model of casting molding machine were finally finalized and unified in 2018, and all other models of casting molding machines thereafter have also adopted the same configuration or upgraded based on this configuration. The hydraulic device adopts German Siemens frequency conversion combined with Japanese oil Yan hydraulic valve group and pump station, which can ensure stable operation and reliability without stopping for a long time, and is relatively quiet during low-noise operation; At the same time, the design of its frequency conversion is also aimed at energy conservation. When the machine is in standby or there is no compaction behavior, the hydraulic device will enter an idle state.

Under normal circumstances, the control system is equipped with Omron PLC, sensors, safety gratings, and Omron 10 inch touch screen display; One click switch between automatic or manual shaping, automatic detection and prompt of faults, automatic safety warning emergency stop, and automatic adjustment of hydraulic station temperature rise, cooling, etc; We can also replace electrical components from other brands based on the user's location, so that users can quickly obtain accessories and related services from brand manufacturers during the later use, maintenance, and repair of equipment;

The most commonly used and ideal sand box size range for this casting molding machine is 510mm-650mm, and the most suitable sand shooting pressure is between 0.52-0.60. After the sand box is closed, there should be a gap of 70mm-85mm between the compacted plate inside and the highest point of the mold. When meeting the above three conditions and retaining sufficient outer sand margin, high-quality casting sand can also be used to achieve excellent production of most types of castings.