-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

On September 17-19, 2025, members of Zoomzu's team will travel to Bangkok, Thailand to participate in the 2025 Southeast Asia (Thailand) International Metallurgy and Foundry Exhibition

click : 325

ZOOMZU has established an office in India and is preparing storage parts to ensure fast and efficient after-sales and service for each automated casting molding machine

click : 202

At normal temperature and humidity, the casting sand mixing ratio suitable for automated molding lines is: mixing ratio (weight ratio) casting old sand 95%, new sand 3%, bentonite 0.8-1.0%, coal powder 0.4-0.5%, water accounts for 3% of the total weight of all materials (not exceeding 3%);

click : 439

The 2023 Summary and Commendation Conference of Meibang Group, with the theme of technology as the king and service as the foundation, and the 2024 New Year's Meeting were held as scheduled

click : 629

The 14th International Foundry Expo in 2023 was held as scheduled in Dusseldorf, Germany. After four years, we came to the exhibition again as a foundry equipment manufacturer to participate. The booth is C53-7 in Hall 17;

click : 677

In the process of transitioning from traditional casting enterprises to mechanized and automated casting workshops, it is very important to have a reasonable layout and planning of the workshop site; Mainly including: area allocation of casting workshop, layout of casting equipment, environmental requirements, and protective measures to be taken (safety protection);

click : 673

After starting the molding machine, run the hydraulic device first. The equipment can only be operated normally after the hydraulic device reaches the normal oil temperature; 2. Regularly check the lubrication pump of the molding machine. When the oil level in the lubrication pump's oil tank is insufficient, lubricating oil should be added in a timely manner;

click : 596

The green sand automated foundry mainly consists of melting equipment, sand mixing equipment, molding equipment, pouring equipment, cleaning equipment, testing equipment, processing equipment, etc;

click : 378

The common automated casting and molding production lines for tidal sand (clay sand) mainly include vertical parting box less injection molding line, horizontal parting box less injection molding line, and multi contact static pressure box molding line. In the past decade of rapid development and widespread application, machine automatic molding technology, automated pouring, and automated sand mixing and sand making technology have become very mature. Currently, most casting molding lines work on the principle of using pneumatic sand addition and hydraulic compaction to achieve automatic molding of sand molds.

click : 408

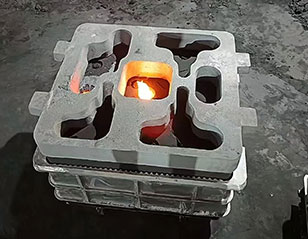

The chemical composition of ductile iron castings must be strictly controlled, otherwise it is difficult to meet customer requirements. Strictly control the process from the selection of raw materials, formulation of smelting process, temperature control, and pre furnace spheroidization incubation treatment. Below, we will summarize and introduce the key points of ductile iron smelting and spheroidization treatment!

click : 405

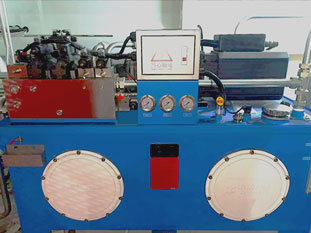

On June 15, 2021, we upgraded the configuration of the upper and lower sand injection hydraulic system, adding a new design scheme with two different versions for users to choose from.

click : 330

The main material used is aluminum or ductile iron (QT) material, which is cast and formed. The frame sleeve is finely processed into serrated and inclined concave and convex patterns using a milling cutter, ensuring that the sleeve box and sand mold can be accurately and tightly fitted. At the same time, it is beneficial for the sand mold to dissipate heat and exhaust around the cavity during the pouring process.

click : 477

On the morning of January 11, 2020, under the leadership of Chairman Lu of China Casting Machinery Corporation, Meibang Group officially entered the 2019 annual meeting celebration and commendation ceremony. The ceremony was held at 9:00 am to summarize the past work reports for 2019 and plan the company's development direction for 2020, preparing for the challenges and new opportunities faced in 2020.

click : 616

The year-end is approaching, and 2020 is about to kick off. On the occasion of the arrival of the Chinese New Year, Mr. Lu, Chairman of Zoomzu Corporation, prepared a New Year gift for all employees' families and delivered it to each employee's home by express delivery, sending New Year greetings and sincerest wishes to all employees of the group.

click : 599

The main function of the clay sand processing line is to recycle and reuse the old sand from the molding line. After being processed through steps such as sand falling, crushing, and screening, it is mixed with new sand to provide sand for the molding line molding host again. In normal operation and production, the fully automatic horizontal molding line can be equipped with a clay sand processing production line with a processing capacity of 20T per hour for single machine sand boxes within the range of 420mm-610mm.

click : 714