-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

This device has become the mainstream model in the current application market with the most ideal sanding method. In order to adapt to different environmental temperatures in various regions and the requirements of different users for molding speed, on June 15, 2021, through joint discussions between the electrical technology team and the hydraulic design team, we decided to add one new design scheme with two different configurations for users to choose from.

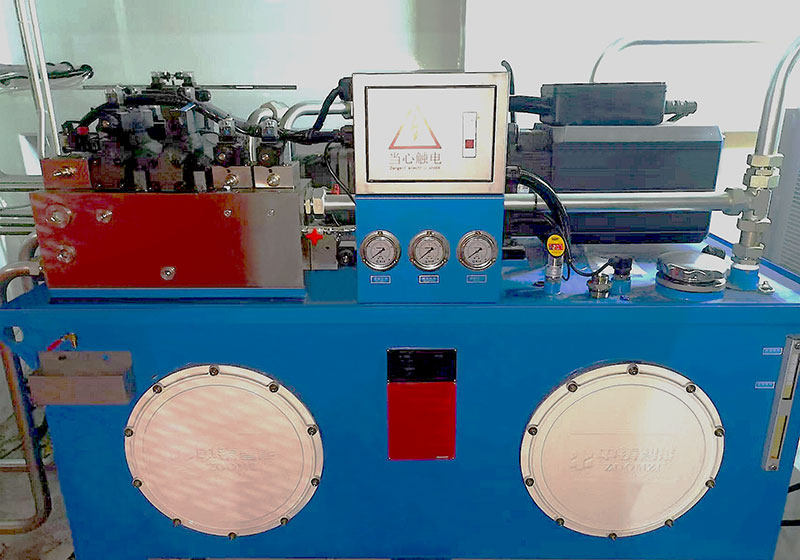

In terms of the hydraulic station configuration of the conventional top sand blasting+bottom sand blasting molding machine, we still continue the design of a single servo motor and a single oil pump to provide hydraulic power output for compaction and machine sand box movement; For users who pursue modeling speed, they can choose to install a higher configuration and high-power hydraulic system, which uses a hydraulic assembly with dual servo motors and dual oil pumps. The main oil cylinder (i.e. compaction cylinder) of the modeling machine is controlled by a single servo motor and an oil pump. The up and down movement of the machine's sand box and the pushing and retracting of the pushing cylinder are controlled by another set of servo motors combined with the composition of the oil pump. At the same time, the hydraulic station of this configuration is designed with two oil tanks and equipped with a 60KW forced air cooling component to accelerate the cooling of the oil temperature and separate the storage and circulation of high-temperature hydraulic oil and cooled hydraulic oil;

The new configuration has also increased the total power of the hydraulic station, with a total power of 24KW in the size range of 510mm-600mm, 31KW in the size range of 610mm-850mm, and 36KW in the size range of 860mm-1300mm.