-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

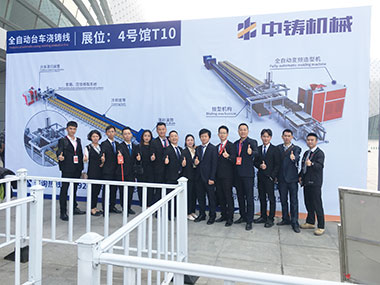

The Shandong Weifang Casting Equipment Exhibition was held as scheduled from October 18th to 20th, 2019 at the Shandong Lutai Exhibition Hall in Weifang. Zoomzu was invited by the Shandong Casting Association to participate in this exhibition as a casting equipment supplier. The exhibition equipment mainly includes fully automatic horizontal parting molding machines and fully automatic horizontal parting molding lines, with a total of 14 attendees mainly consisting of sales and installation teams! The exhibition location is set at position T10;

click : 574

the founding conference of the Melting Technology and Equipment Branch of the China Foundry Association was grandly held in Weifang, Shandong on August 12, 2019.

click : 404

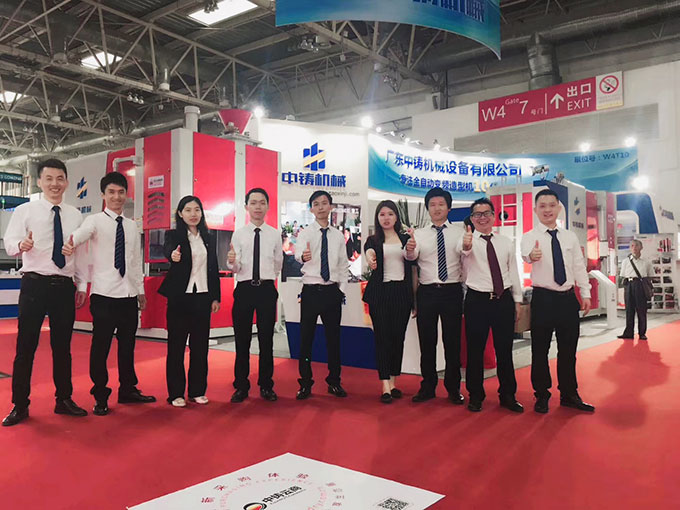

Zoomzu participated in the 14th International Foundry Expo (GIFA2019, held every four years) held in Dusseldorf, Germany in July 2019

click : 519

Before the Mid Autumn Festival on August 15th, 2019 in the lunar calendar, Chairman Lu was preparing personally signed greeting cards and packaged holiday gifts for the employees of the group headquarters, sending good wishes and gratitude to their families to every employee of the company. All employees were also given one day off according to the statutory holiday.

click : 3550

The ZOOMZU team, as an automated casting equipment manufacturer, actively responded to and participated in the casting feast organized by the China Foundry Association. On March 11, 2019, they arrived at the Shanghai International Expo Center to arrange the exhibition and related matters

click : 517

Based on the feedback from the operator, such as the inconvenience of observing the interior of the mold cavity and the inability to accurately and quickly place the core when placing a large core in the mold cavity, the person in charge proposed on September 5, 2018 to design a sand box drawing function for conventional casting molding machines;

click : 272

On December 26, 2018, the headquarters of the group held the 2018 annual work summary and commendation meeting and the 2019 company development planning meeting as scheduled. The ZOOMZU team's four departments, including the technical research and development department, sheet metal assembly department, sales department, and after-sales technical department, arrived at the scene to attend the meeting

click : 400

The development of enterprises cannot be separated from the development of automation and mechanization, which is also a stage that enterprises need to go through; The following will introduce the advantages of casting enterprises using automated casting equipment in production compared to traditional manual casting:

click : 576

We will specifically introduce several methods for the sand mold of the horizontal parting casting molding machine to timely discharge the gas generated by high temperature in the mold cavity during the pouring process of molten metal:

click : 748

The 13th China International Casting Exhibition, hosted by the China Foundry Association on May 16, 2018, was grandly held at the Beijing Exhibition Center in the capital of China. As a manufacturer of automated casting molding equipment, the Zoom team responded to the warm invitation of the China Foundry Association and actively participated in this international casting exhibition.

click : 483

On November 11, 2017, Mr. Zhi Xiaoheng, Executive Vice President of China Foundry Association, Mr. Jing Liwen, Assistant Minister of Education and Training Department, and Mr. Zhao Zhili, an expert and professor at Shenyang University, visited ZOOMZU to inspect the work

click : 478

Donate books, learning stationery, computers and other educational supplies to rural primary schools, support the development of education in rural areas, and care for the learning and physical and mental health of young people and children.

click : 399

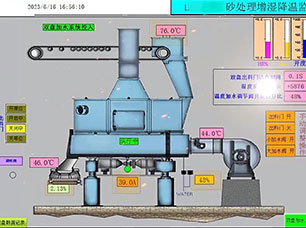

There are many factors that need attention and treatment in the treatment and mixing of tidal sand. If one or more critical conditions cannot be maintained within the control range, the mixed wet sand without good conditions will directly affect the quality of the generated castings

click : 583

The fundamental difference between the traditional semi-automatic molding machine and the fully automatic horizontal parting casting molding machine lies in the fact that the automatic molding machine uses hydraulic cylinders to compress the sand inside the sand box in one go and with high strength, which has certain requirements for the hardness and strength of the mold to avoid damage to the mold when the compaction pressure increases during the sand mold compaction process;

click : 758

Below is a brief analysis of the identification methods for ductile iron castings and gray iron castings for everyone

click : 375