-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

Based on suggestions from some casting enterprise users who have been using ZOOMZU's product equipment for many years, and combined with feedback from operators on certain special usage situations, such as when placing large cores in the mold cavity, the state of the sand box is not convenient for the operator to observe the inside of the mold cavity and it is impossible to accurately and quickly place the cores. On September 5, 2018, the person in charge proposed that ZOOMZU's technical team and sheet metal assembly team members unanimously decided to design and improve the drawings of the conventional equipment based on conventional automated molding machine drawings.

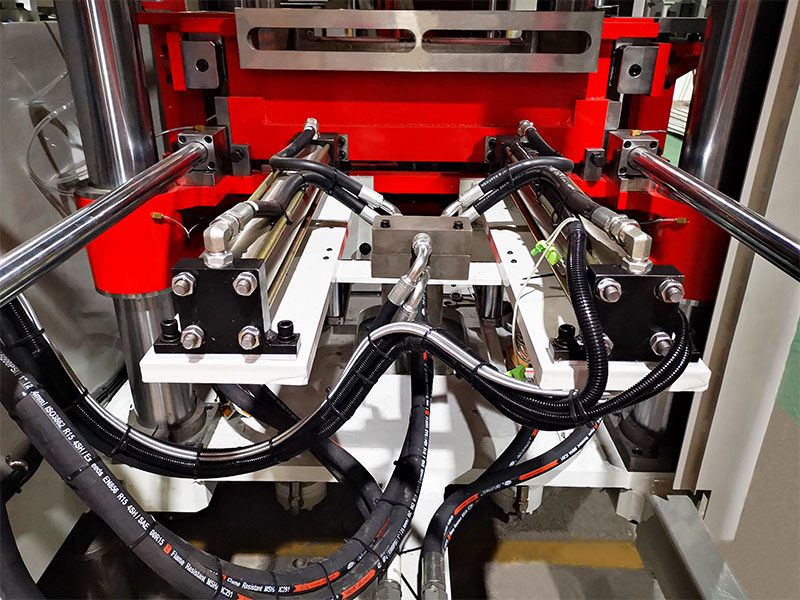

The lower sand box of the modeling host adopts an embedded design, with stainless steel precision guide rails and positioning slots added on both sides of the lower sand box; Install a fixed support for the oil cylinder on the original rack drawing and keep it level with the bottom of the lower sand box. Install the oil cylinder with a limit device on the fixed support to push the sand box to draw and retract, ensuring accurate movement of the sand box and preventing the sand mold from being misplaced during later box closing; Based on the weight of the sand mold and sand box, as well as the force analysis under various states, design the overall sliding stroke of the sand box to be half the width of the sand box; Install brackets and protective plates on the outer side of the sand box located at the tail of the guide rail to ensure the horizontal consistency and safety of the sand box within the movable range, and modify the program button to execute this action through the operator's selection of yes or no;