-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

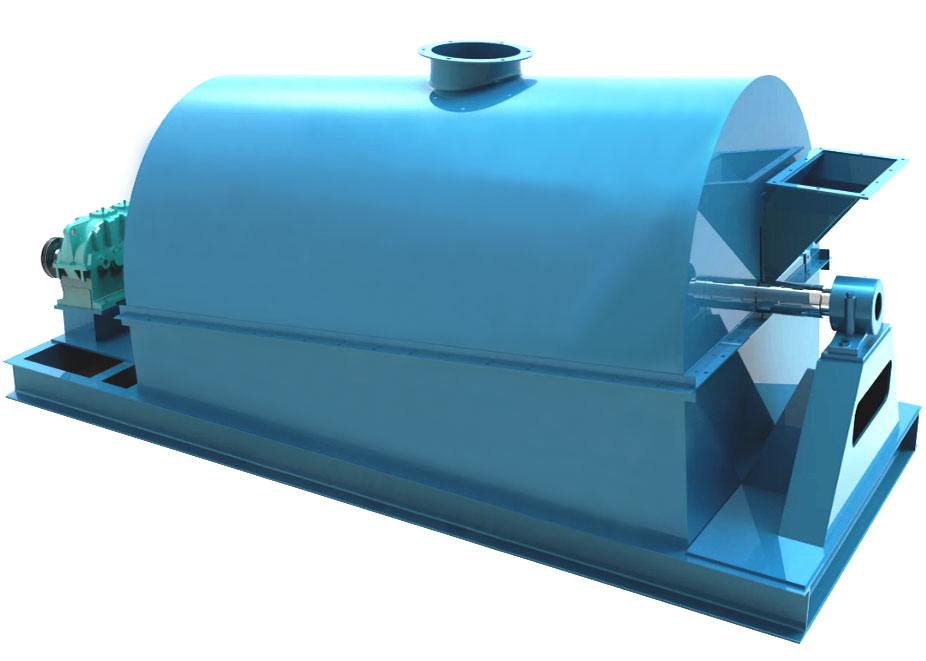

This equipment is used for preliminary screening of cast sand, secondary crushing of smaller old sand blocks, and dust removal and cooling. The built-in hexagonal cylindrical screen of the equipment has a certain inclination angle. Through continuous rolling of the cylindrical screen, the old sand blocks are crushed, and the old sand in powder state enters the next processing process. The hardened sand blocks, coated sand cores, and small iron blocks that cannot be broken will fall off and be collected in waste bags due to their tilted state. The dust generated during rolling screening will be removed by installing ventilation and dust removal equipment to reduce the sand temperature of the old sand.

1. It has functions such as crushing, screening, and cooling, with a sieving rate of 97%;

2. The dust removal port provides strong ventilation to remove some dust from the old sand, reduce the mud content, and achieve a certain cooling effect;

3. The truss type screen body structure is a seamless steel pipe welded structure, with high overall rigidity and high fatigue resistance;

4. Spindle processing, high concentricity, positive dynamic balance effect, smooth operation, low noise;

1. The drum screening equipment is used as a primary screening device in the automated clay sand treatment system, and is normally designed and installed at high points connected to the old sand recovery belt or bucket elevator; The most widely used equipment for screening clay sand in current casting enterprises is the horizontal truncated hexagonal prism drum screening equipment, also known as the fine hexagonal screening machine;

This machine mainly consists of a frame, a screen barrel frame tilted on the frame, a hexagonal screen frame coaxially arranged with the screen barrel frame, and a driving device that controls the rotation of the screen barrel frame.

The higher end of the screen frame is equipped with a feeding hopper, which is equipped with a vibration motor. The lower end of the hexagonal screen frame is equipped with a discharge hopper, and the outer cover of the screen frame is equipped with a dust cover, with two inspection ports on the dust cover.

2. In the early days of clay sand (tidal sand) drum screening equipment, cylindrical drum screening machines were mainly used, while hexagonal prism drum fine screening machines were later improved and upgraded derivative screening machines based on practice; The biggest difference is that the bumps and collisions generated by the hexagonal prism drum screen during high-speed rotation can better crush the old sand blocks.

3. Φ 3.5 High strength and high hardness cold drawn stainless steel wire woven screen mesh, with requirements for wear resistance, high strength, and high impact resistance, is not easy to rust and damage, and has good rebound and crushing effects. The hexagonal drum screen mesh is fixed by mutual tension, with bi-directional bolts tensioning the screen mesh, and the mesh surface is tight to keep the screen mesh tightly against the frame, without sand leakage, and is easy to disassemble and replace;

4. In the recycled old sand, there are coated sand cores and granular sand clusters that have hardened after combustion. If they are not screened and directly enter the molding sand on the molding line, it will cause damage to the sand mold cavity after the automatic molding machine demoulds, thereby affecting the yield and surface smoothness of the casting.