-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

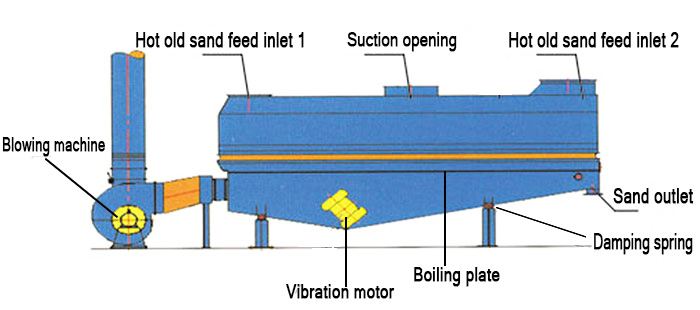

This equipment is used for conveying, cooling, and dust removal of old sand (hot casting sand) that is recycled in the self hardening sand and clay sand process in the casting workshop. It is an ideal heat exchange and cooling cooling device.

1. Special sand cooling fluidized bed pores will not cause blockage of the gas nozzle by the sand material, which will affect the air supply;

2. Pores are evenly and densely distributed on the fluidized bed surface, resulting in excellent gas distribution effect;

3. Equipped with a dust outlet connected to the dust removal system, it can timely remove the dust separated during the heat exchange process and purify the sand material;

4. Simple structure with low failure rate and maintenance cost, suitable for automated clay sand treatment line of 20T-40T;

In clay sand casting, we need to recycle and reuse the broken old sand after pouring. In the process of recycling old sand, it is necessary to quickly restore the high-temperature old sand to a certain temperature and remove the dust in the old sand. Otherwise, if the cooled high-temperature old sand is reused in casting production, it will cause various surface defects on the casting. The vibration boiling cooling bed is a casting sand treatment equipment that cools and removes dust from high-temperature old sand.

2. The vibration boiling cooling bed mainly includes: bed body, vibration motor groups on both sides, fish scale shaped pore boiling plate horizontally placed inside, blowing system, exhaust system, and other components. The horizontal and inclined boiling plate divides the bed into an upper cooling chamber and a lower air inlet chamber, with air inlet and air outlet respectively set in the air inlet and cooling chamber;

3. Loose and high-temperature old sand enters from the old sand mouth above the cooling bed and falls on the vibrating fish scale shaped pore boiling plate. Under the excitation force of the vibration motor, the sand moves forward in the direction of vibration and inclination. At the same time, under the strong blowing effect of the high-pressure fan, low-temperature or room temperature cold air enters the lower part of the cooling bed through the air inlet and flows to the upper cooling chamber through the pores on the boiling plate, causing the high-temperature old sand to boil. The air and hot sand are fully in contact, and the high-temperature old sand achieves a certain degree of cooling. Finally, the hot air, dust, and water gas in the old sand are extracted by the exhaust fan, The extracted gas is discharged after being processed by the dust removal system. The cooled old sand is continuously transported to the sand outlet of the cooling bed. The heat exchange between sand and air in boiling state is 6-10 times greater than that in static state, making a fluidized bed an ideal heat exchange device.