-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

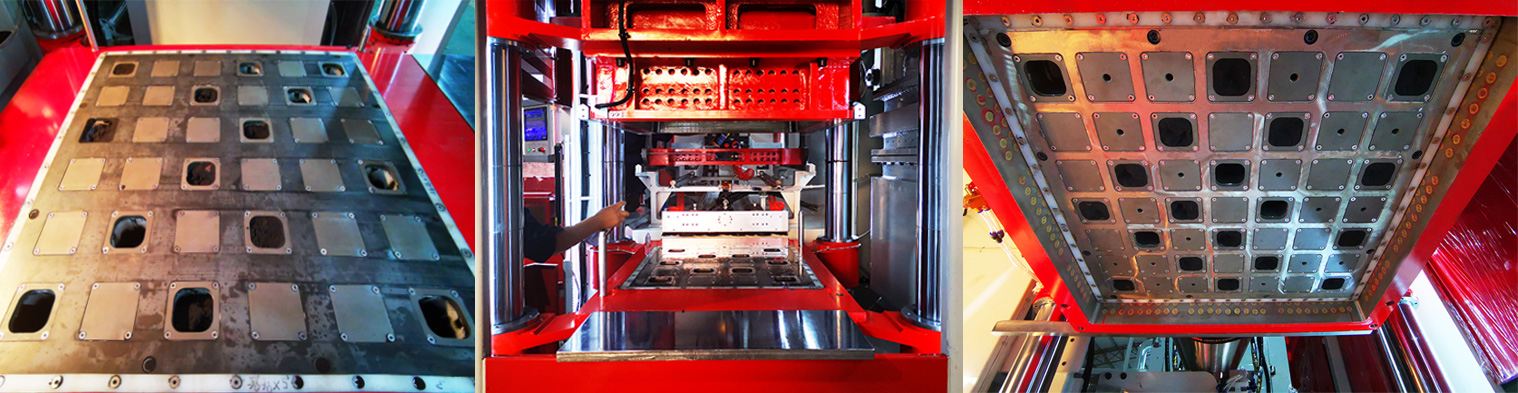

The design adopts independent sand injection and filling sand at the top and bottom, with the aim of making the sand filling method closer to manual molding, ensuring that the internal of the sand box can obtain a more uniform compactness when forming the sand mold, and allowing more complex or large concave and convex molds to be made into perfect sand molds through automatic molding machines. This machine is also a derivative of conventional automatic molding machines, so it has been widely recognized and used by many casting enterprises in recent years.

1) Sandbox size range: 550mm -950mm;

2) The unique sandblasting method makes the filling of casting sand more uniform and compact;

3) Suitable for automated casting and modeling of various and complex types of castings;

4)The total height of the sand mold is 400mm-600mm (adjustable height);

5)Modeling speed of 80-90 sand molds per hour (time without core placement);

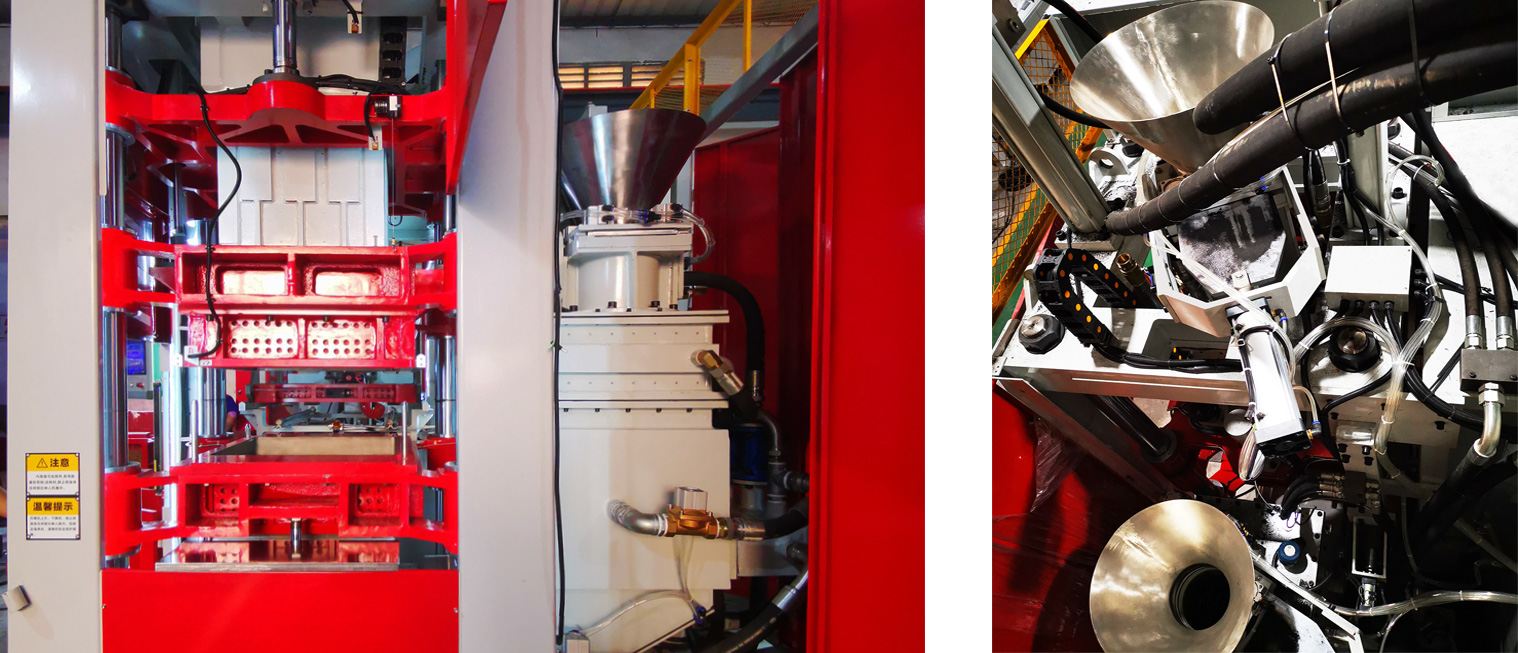

The sandblasting method machine of this sand casting molding machine was developed and put into use in 2018. After 4 years of research and development, based on user feedback and our repeated experiments, a new type of sand casting molding machine was upgraded and launched in 2022. The main solution is to solve the problem of sand blasting mouth blockage in sand casting molding machines using this type of sandblasting method after long-term use of sand with high humidity and poor sand flowability. The launch and use of the new machine have received unanimous praise from users, and so far, the maximum customizable sand box size range has covered 1200mm. The larger the sand box size, the higher the requirements for the machine's sandblasting performance, which also indicates that the new horizontal parting molding machine for top and bottom sandblasting has a stable sandblasting system;

2. During normal use, the sandblasting ports of the upper and lower sandboxes can be selectively opened by half. Under the same air pressure and time, opening half of the sandblasting ports and opening all of them can complete sandblasting in the same time. That is to say, under the same air pressure, the number of sandblasting ports decreases and the sandblasting speed increases (referring to only opening half of the sandblasting ports); It is precisely because of this design that we can open the corresponding sandblasting port to perform targeted sandblasting on specific positions of the mold when using this machine for molding, making the sandblasting effect and the uniformity and pre compaction of the sand mold cavity before compaction more ideal.

3. In terms of machine structure, we have adopted a design of two sand storage cylinders for molding sand. The sand storage cylinders for the upper and lower sand boxes are independently separated, allowing each cylinder to perform corresponding sand box sandblasting. This greatly reduces the load on the sandblasting system for machines with large-sized sand boxes, and a mesh hole 304 stainless steel breathable plate is installed on the inside of the sandblasting cylinder; This sand casting molding machine adopts a new design in the intake pipe and gas guide system, allowing the molding machine to easily and smoothly complete sandblasting with lower air pressure during operation; The connection between the sand box and the corresponding sand storage cylinder has been sealed for airtightness, ensuring that there is no air leakage or dust flying during the sandblasting process, and making the sandblasting system more stable and durable; And there are also reserved cleaning and maintenance ports at the bottom of the sand storage cylinder, as well as hydraulic maintenance space at the bottom of the machine;

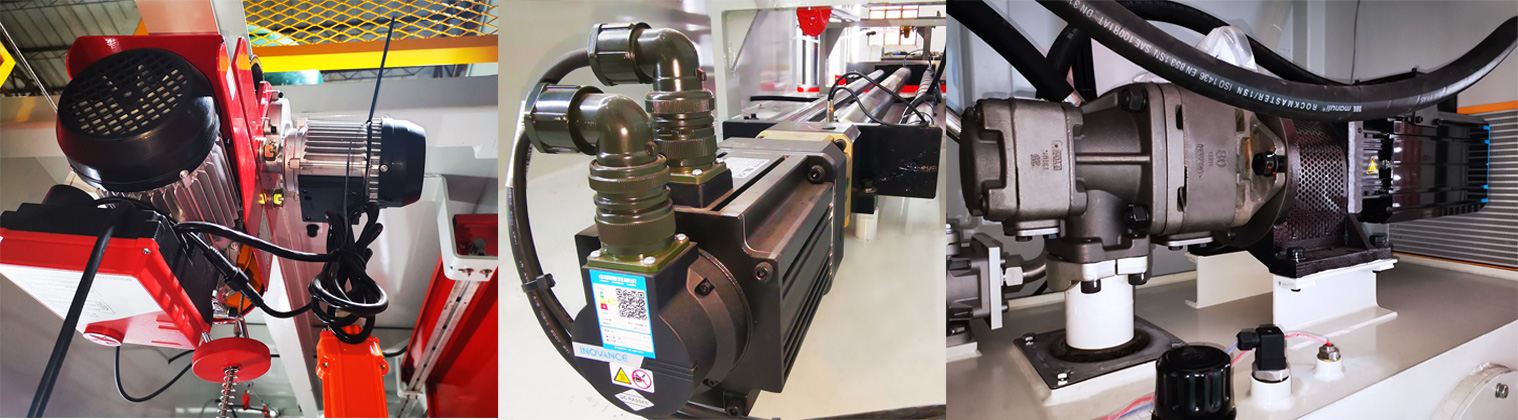

4. The new top and bottom sandblasting sand casting molding machine is equipped with a mold lifting device, which facilitates operators to quickly and easily replace molds; The sand mold pushing device adopts servo electric cylinder for independent control, which makes the operation more stable and convenient for precise adjustment and control; Servo motors have also been used in the hydraulic assembly, which have fast and accurate response speed, as well as the ability to handle more complex program instructions; In addition, comprehensive intelligent design has been made for the safety warning and fault display of the entire machine. The purpose of these changes is to make the machine more practical, durable, and reliable during use;

5. The automated sand casting molding machine for top and bottom sandblasting is more versatile for molds with complex and deep concave shapes, and has the highest coverage rate in the production of various castings. This is also a comprehensive automated sand casting molding machine that we have developed after years of repeated experimentation and summarization;