-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

The automated electrical control system is used to achieve automated operation of the casting sand processing line in daily use, allowing each individual equipment in the processing line to cooperate and link with each other, forming a closed and complete process and processing system. Therefore, the electrical control system is also an indispensable part of the sand processing system.

1. Accurately control the start-up and operation of each device, making it easy to operate the equipment ;

1. Realize the automation operation of the casting sand mixing system and form a complete processing flow ;

3. Facilitating the adjustment and recording of various parameters during the mixing process of casting sand ;

4.Provide electrical protection for equipment and monitor its operating status more intuitively;

The automated electrical control system is used to achieve automated operation of the casting sand processing line in daily use, allowing each individual equipment in the processing line to cooperate and link with each other, forming a closed and complete process and processing system. Therefore, the electrical control system is also an indispensable part of the sand processing system, mainly including the following aspects:

Precise control of equipment operation:

Motor control: Accurately control the start, stop, speed and other parameters of each motor in the sand processing equipment, such as the motors of the belt conveyor, bucket elevator, rotor sand mixer, dust removal equipment fan, cooling belt motor, etc., to ensure that the sand material can be transported between various devices according to the set process and speed, ensuring the continuity and stability of production.

• Feeding control: Accurately control the feeding equipment, adjust the feeding amount of sand according to production needs, so that the amount of sand entering each processing stage meets the process requirements, and avoid affecting the quality and efficiency of sand processing due to excessive or insufficient feeding.

Optimize the production process:

Parameter adjustment and optimization: Operators can easily adjust various parameters such as sand mixing time, water addition, ventilation, etc. through the electronic control system according to different sand mixing requirements, in order to optimize the sand treatment effect, meet the requirements of different casting production for sand mixing, and make quick and flexible adjustments during the mixing process.

Data recording and analysis: The electronic control system can record various data during the sand processing process, such as equipment operating time, fault records, process parameters, etc. By analyzing these data, it can help identify problems in the production process, provide a basis for process improvement and equipment maintenance, thereby improving production efficiency and product quality, and reducing production costs.

Implement automated operations:

Process automation: By writing programs, various stages of sand processing, such as screening, sand mixing, cooling, etc., are logically integrated to achieve automated operation of the entire sand processing process, reduce manual intervention, and improve production efficiency and product quality consistency.

• Fault diagnosis and alarm: Real time monitoring of the operating status of various equipment in the sand processing system. When a fault occurs, the fault point can be quickly and accurately located, and an alarm signal can be issued. At the same time, corresponding protective measures can be automatically taken, such as stopping the operation of relevant equipment to avoid the expansion of the fault and facilitate timely maintenance by maintenance personnel.

Ensure production safety

• Safety interlock control: Set up safety interlock devices to ensure that the equipment can only be started when all safety conditions are met during operation, preventing safety accidents caused by misoperation or equipment abnormalities. For example, the relevant equipment can only be activated when the protective door is closed in place.

Overload protection: When the equipment experiences overload, the electronic control system will automatically cut off the power or take measures such as speed reduction to protect the equipment motor and other components from damage, while also avoiding safety hazards caused by equipment overload.

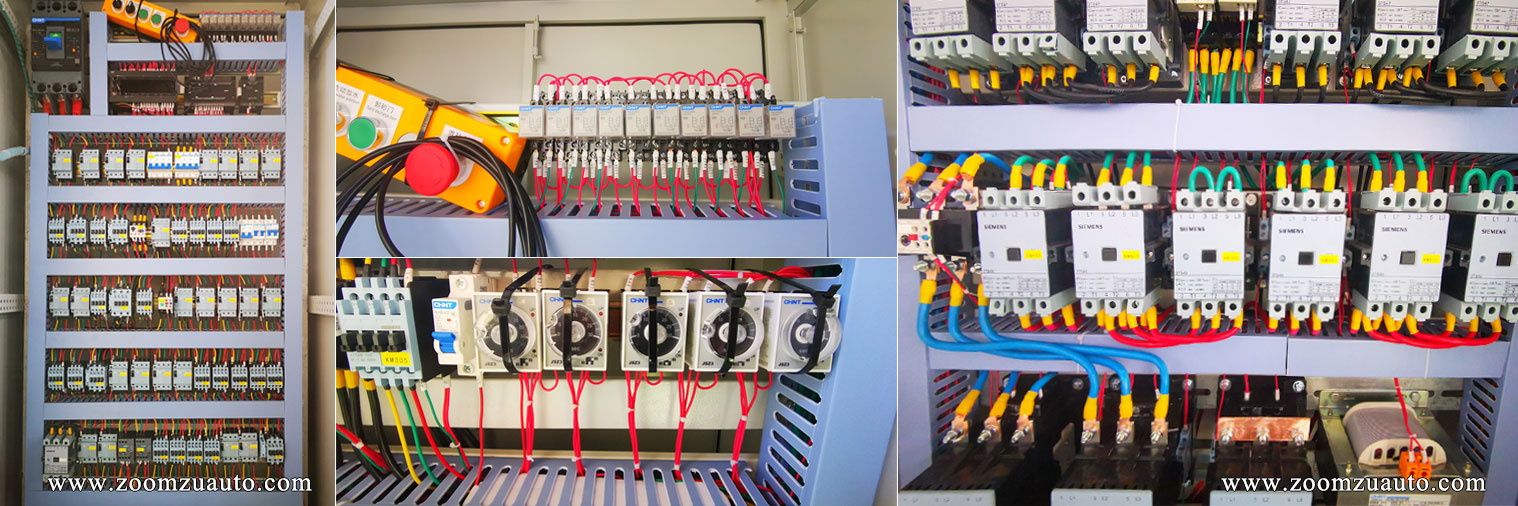

The control cabinet has an IP54 rating, dust-proof rating of 5, and waterproof rating of 4, ensuring high sealing of the control cabinet and effectively preventing particles and dust from entering, providing reliable protection for the equipment.

The electrical components adopt Siemens PLC and protectors, Schneider (LC1D series) contactors and relays, ABB modules and frequency converters and soft starters (ACS series), Chint timers, etc; Of course, we can also choose to match the electronic control system according to the user's brand usage requirements for electrical components;