-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

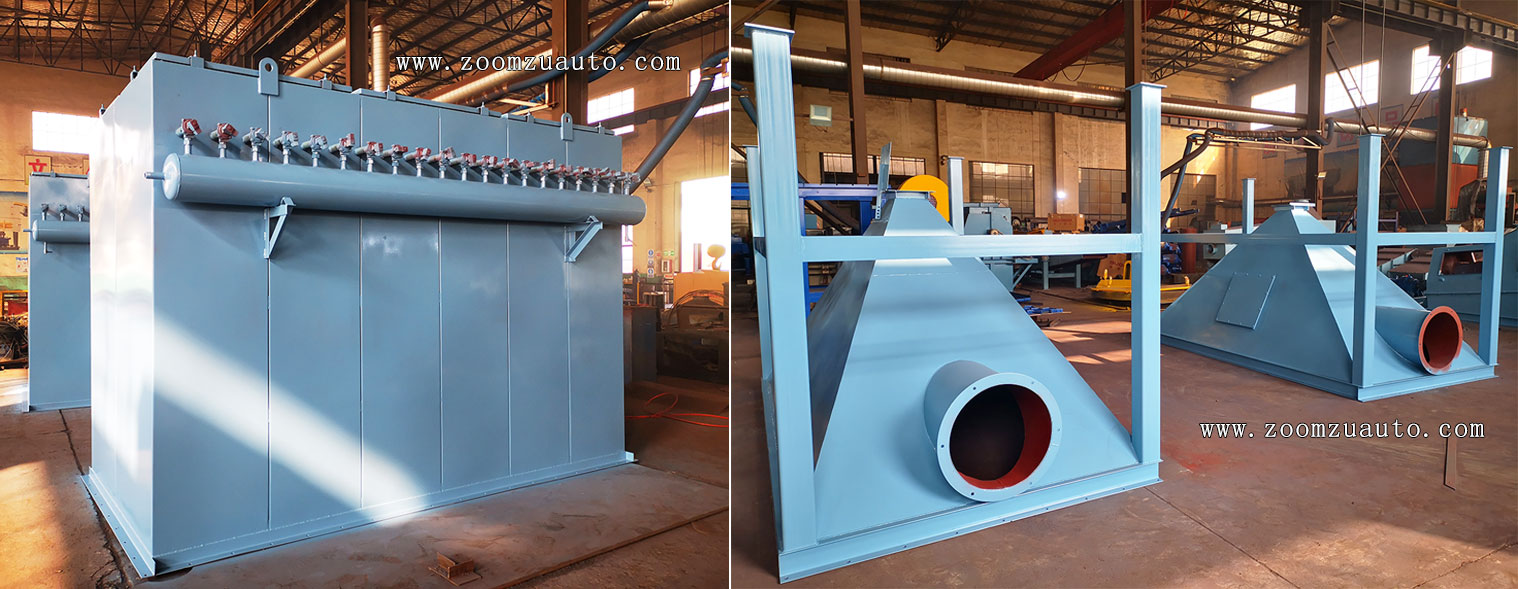

The dust laden gas is sucked into the dust collector through the induced draft fan, and filtered by the filter bag. The dust is trapped on the outer surface of the filter bag, while the clean gas is discharged through the inside of the filter bag. When the dust accumulation on the outer surface of the filter bag reaches a certain level, the control system will issue a command to open the pulse valve and blow compressed air into the inside of the filter bag, causing the filter bag to instantly expand and vibrate, thereby shaking off the dust attached to the outer surface of the filter bag into the ash hopper, achieving the purpose of cleaning the dust.

1. Pulse bag filter has high filtration efficiency, can capture small particles, effectively purify the air, and has a large processing capacity;

2. Automatic dust cleaning: The pulse bag filter adopts an automatic dust cleaning system, which does not require manual intervention and ensures the continuous operation of the equipment;

3. The cleaning method of pulse bag filter is energy-saving and environmentally friendly, and does not require additional consumption of a large amount of energy;

4. The structure is relatively simple, and the connection and disassembly of each component are convenient. Easy to operate, easy to install, easy to maintain, and easy to repair. The cleaning effect is good, the operation is reliable, and the service life is long. In daily use, only regular inspection, cleaning, and replacement of the cloth bag are needed, and the maintenance work is relatively simple and convenient.

Pulse bag filter is an important supporting equipment in a standard wet mold sand processing production line and green sand processing production line. Normally, we use two sets of bag filter equipment with different air volumes in the old sand screening and cooling stage and vibration sand dropping stage of the casting sand processing system. The single machine equipment in the old sand processing system is connected to the dust collector through a suction pipe, and the air volume of the dust removal equipment needs to be reasonably selected based on factors such as the hourly old sand processing capacity of the old sand processing system, the length of the pipe, the number of connection ports, and the number of bags; The main function of the bag filter in the casting sand processing system is to timely extract dust from the old sand, dust from the combustion of coated sand, and some hot gases from the old sand into the filter before discharging, so that the molding sand can maintain good breathability and flowability during repeated cyclic use;

In the application of pulse bag filter matched with wet mold sand treatment line, it is recommended to install the dust removal equipment outside the workshop if conditions permit, in order to reduce the occupation of the workshop area by the equipment and minimize the length of the suction pipe as much as possible;

The principle of pulse bag filter:

The dust laden gas is sucked into the dust collector through the induced draft fan, and filtered by the filter bag. The dust is trapped on the outer surface of the filter bag, while the clean gas is discharged through the inside of the filter bag. When the dust accumulation on the outer surface of the filter bag reaches a certain level, the control system will issue a command to open the pulse valve and blow compressed air into the inside of the filter bag, causing the filter bag to instantly expand and vibrate, thereby shaking off the dust attached to the outer surface of the filter bag into the ash hopper, achieving the purpose of cleaning.

In foundries, pulse bag filters are mainly used in the following areas:

1. Sand making: During the sand making process, a large amount of dust is generated. By installing a pulse bag filter, it is possible to effectively collect these dust particles and reduce environmental pollution.

2. Smelting process: The smelting furnace produces a large amount of smoke and dust when melting metal. Pulse bag filter can efficiently capture these smoke and dust, ensuring the air quality in the workshop.

3. Pouring process: During the pouring process, a large amount of smoke and dust will be generated when the metal liquid comes into contact with the sand mold. Pulse bag filter can quickly capture these smoke and dust, keeping the production environment clean.

4. Cleaning work: In sand casting plants, cleaning work is also an important step in generating dust. Pulse bag filter can effectively collect the dust generated during the cleaning process, reducing the labor intensity of workers.

Composition of Pulse Bag Dust Collector:

1. Dust collector box: generally made of welded steel plates, with internal partitions to separate different working areas. The box has good sealing to prevent dust leakage.

2. Ash hopper: located at the bottom of the dust collector box, used to collect filtered dust. The bottom of the ash hopper is equipped with an ash discharge valve, which facilitates regular cleaning of dust.

3. Filter bag: The core component of a dust collector, made of high-quality filter material, with good filtration performance and corrosion resistance. The filter bag is supported by a skeleton inside the dust collector, forming a filtering layer.

4. Spray system: a device used for cleaning dust, which sprays compressed air into the filter bag through a pulse valve, causing the filter bag to instantly expand and shake off the attached dust. The spraying system is usually linked with the control system to achieve automatic dust cleaning.

5. Inlet and outlet: The inlet is equipped with a guide plate to evenly distribute the dusty airflow into the dust collector; The air outlet is connected to the exhaust duct to release the purified gas into the atmosphere.

Maintenance and upkeep of pulse bag filter:

In order to ensure the normal operation and prolong the service life of the pulse bag filter, the following maintenance and upkeep work needs to be done:

1. Regularly inspect the filter bag: The filter bag is the core component of the dust collector and needs to be regularly checked for damage and aging, and replaced in a timely manner.

2. Cleaning the ash hopper: The accumulated dust in the ash hopper needs to be cleaned regularly to avoid affecting the dust removal effect of the dust collector.

3. Check the pulse valve and control system: The pulse valve and control system are key components of the dust collector, and their working status needs to be regularly checked to ensure normal operation.

4. Lubrication and fastening: Regularly lubricate and tighten the transmission components of the equipment to ensure the stability and safety of its operation.