-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

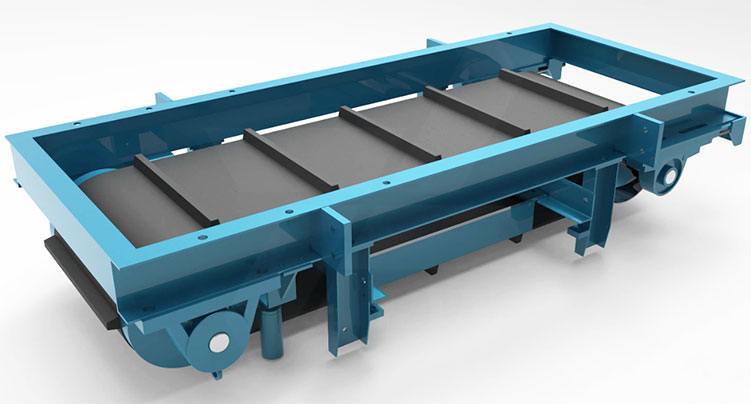

This device is widely used in industries such as metallurgy, mining, and casting. It is used in casting production to adsorb and screen iron blocks doped in old cast sand after pouring, effectively separating magnetic metal objects from the sand layer. The device is designed and installed above the conveyor belt, with an independent support structure suspended by high-strength magnetic magnets and the distance between the magnets and the conveyor belt can be adjusted to control the size of the adsorption force.

1. This machine adopts high-strength magnetic materials, which have the characteristics of strong magnetism, good magnetic separation effect, stable operation, and reliable performance;

2. The magnetic system has slow aging and long lifespan, with a decrease of only 18% in 5-7 years, still close to electromagnetic separation equipment;

3. When the magnetic field decreases, the magnetic system can be removed for magnetization, achieving cyclic use;

In casting, the molding sand used can be reused. The old sand collected by the shaker after vibrating the casting often contains a large amount of iron filings and remaining iron blocks at the pouring and riser. A magnetic separator is needed to collect the iron filings. Generally, 2-3 levels of magnetic separation devices are set up in the old sand treatment system, and suitable magnetic separators are configured according to the efficiency of casting sand treatment and the width of the old sand recovery conveyor belt, The commonly used magnetic separation equipment includes a belt pulley ultra strong magnetic permanent magnet drum and a hanging belt type permanent magnet separator. This device is normally designed and installed on the old sand recovery conveyor belt and in the rollers at both ends of the belt, effectively separating iron impurities that pass through the magnetic separation device in a timely manner to prevent them from entering other sand processing equipment and causing damage.