-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

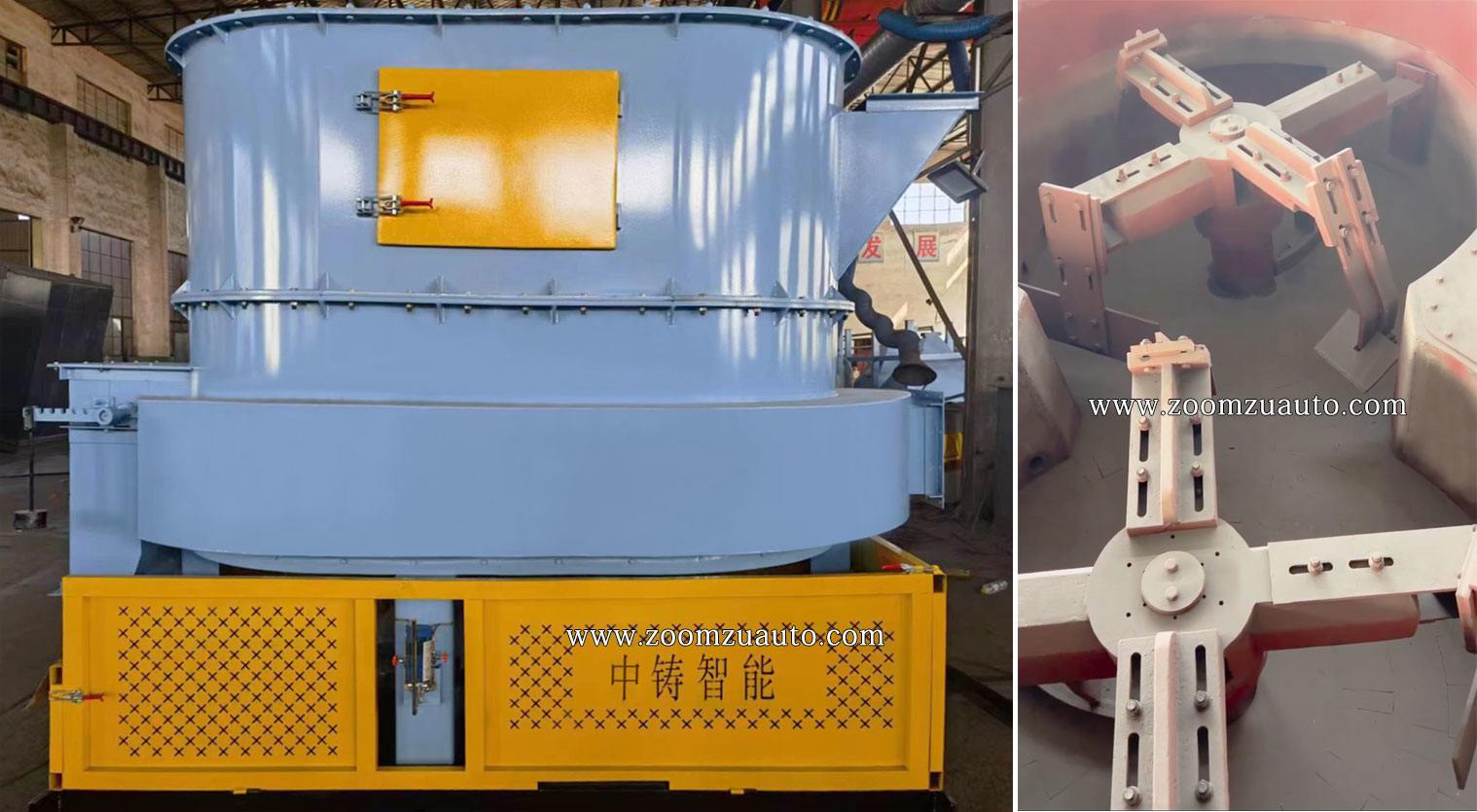

This equipment is mainly suitable for cooling clay sand and old sand. Fully stir and mix the old sand to ensure uniform temperature, humidity, and composition. While cooling, complete the pre mixing process to prepare high-quality molding sand. The equipment has a compact structure, smooth operation, low noise, and low energy consumption; The reverse rotating crosshead drives the scraper to push the material to mix evenly; High pressure air blowing keeps the old sand in a boiling state, achieving cooling effect; The opening of the discharge door can be adjusted to control the emptying of materials in the machine basin;It can be combined with the old sand humidification cooling system, blower, and exhaust fan to form an old sand cooling unit, with good cooling effect.

1. The reverse rotating crosshead drives ten scraper plates to evenly mix the materials, and the bottom surface of the mixing component is made of wear-resistant ceramic material;

2. High pressure blowing keeps the old sand in a boiling state, resulting in better cooling effect;

3. The opening of the discharge door can be adjusted to control the emptying of materials inside the machine box;

4. It can form an old sand cooling unit with the old sand humidification cooling system, blower, exhaust fan, and water adding system, and can control the temperature of the old sand to reach room humidity+10 ° C;

5. According to the different installation positions, the feeding method of this machine can be made into vertical and linear feeding methods, with two unloading directions: left and right.

If the temperature of the sand recycled in casting exceeds 71 ℃, it is considered hot sand. Moreover, when the temperature of the old sand is between 48.8 ℃ and 71 ℃, incompatibility will occur during the mixing process, making it difficult to ensure the quality of the mixed sand. Assuming that the recovered hot sand cannot be effectively cooled and quickly reused in the molding production of the molding machine, it will lead to varying degrees of defects in the castings produced. The double disc stirring and cooling machine is a key equipment that cools the high-temperature old sand recovered from casting at a fast speed to a suitable mixing temperature for the sand mixer. Under normal circumstances, this equipment is used in a wet sand treatment system with an efficiency of 40 tons per hour for old sand treatment.

When the high-temperature hot sand that has been crushed and recycled after pouring is sieved by a drum and humidified with water, the humidified (moisture content is about 4-5%) hot old sand is fed into the machine body through the feeding port. Each sand flow will stay in the machine for 2 minutes and be fully stirred and move in two circular shapes inside the plate. At the same time, a blower is installed at the lower end of the right wall of the cooling box, The outlet of the blower is connected to the ventilation holes arranged on the inner side of the cooling box near the bottom of the tank through air ducts. During stirring, the blower blows cold air into the cooling box to exchange heat with the sand. The hot air is discharged from the top exhaust duct by the exhaust fan. During this process, the hot sand is also pre mixed while cooling, and the cooled old sand reaches three levels of uniformity: uniform temperature, moderate uniformity, and uniform composition, Create favorable conditions for mixing sand with stable performance.