-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

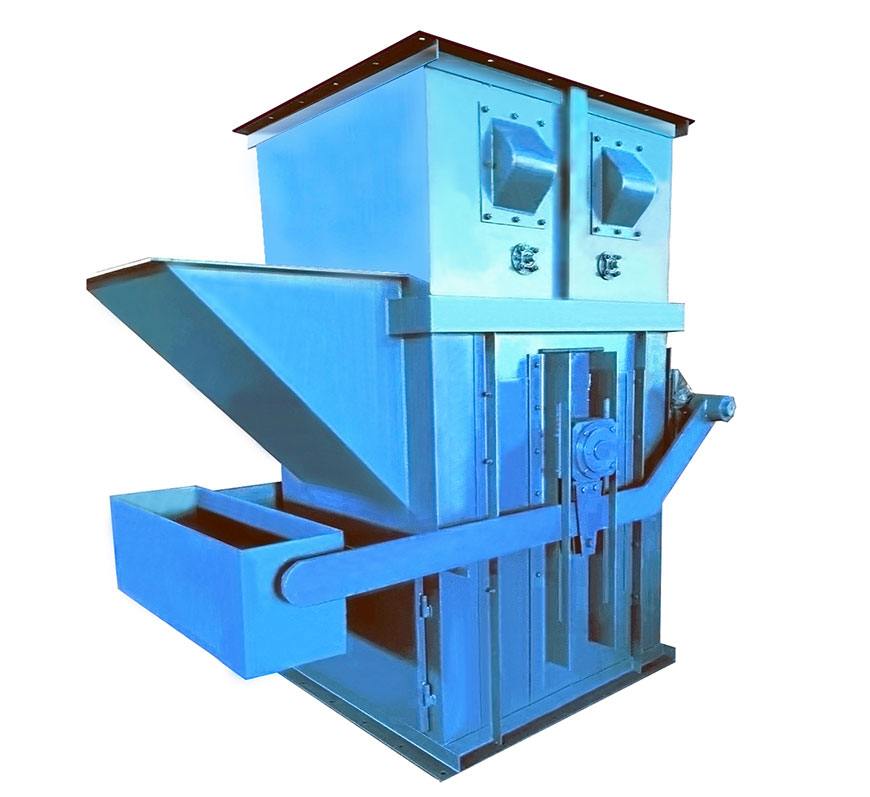

This equipment is a commonly used vertical conveying equipment in mechanized casting workshops, which lifts and transports the bottom material to a specific high position, saving space in the workshop. It is mainly used to lift old sand, waste sand, new sand, clean iron shot and other loose materials;

1. Simple structure, small size, light weight, convenient assembly and maintenance;

2. Large conveying capacity, fast speed, high conveying height, and small footprint;

3. The upgraded materials are not easily damaged and have less pollution;

4. Can be sealed and transported to reduce environmental pollution and ensure the cleanliness of the production environment;

5. Strong adaptability, can be used in air conveying systems for various materials.

The bucket elevator is composed of a hopper, a driving device, top and bottom rollers (or sprockets), heat-resistant tape (or traction chains), a tensioning device, and a casing;

The height of the material bucket elevator is customized according to the actual requirements of the supporting equipment, and the throughput and model size of the elevator are also selected according to the processing capacity of the sand treatment system;

Each individual material bucket elevator is equipped with anti deviation blocking rollers inside to prevent belt deviation, and maintenance doors are reserved for easy cleaning, maintenance, and observation;

1. The transmission device of the bucket elevator adopts a cylindrical reducer and is equipped with a backstop device, making the transmission structure compact and achieving flexible transmission. It can not only ensure smooth operation, but also protect the motor reducer and traction components, and keep the material in a stable state during shutdown.

2. The lower part of the bucket elevator adopts a heavy hammer tensioning device and a bolt adjustment device, which can maintain a constant automatic tensioning force. When the belt elongates, it can be automatically adjusted to avoid belt slipping. The hopper has a certain tolerance for jamming caused by it, which can effectively protect the lower shaft and other components; The weight of the counterweight blocks on both sides needs to be determined based on whether the two sides of the bottom wheel are balanced and whether the lifting belt of the elevator can be tensioned; Adding bolts for fine adjustment can ensure balance on both sides of the bottom wheel, ensuring that the belt does not deviate during operation.

3. Spray paint uniformly after completing assembly, welding, polishing and other processes; Anti rust spraying is mainly divided into bottom paint and external paint. The color of the external paint spraying is matched according to the color of the entire treatment system, and the external paint surface can also be selected for spraying according to user requirements;