-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

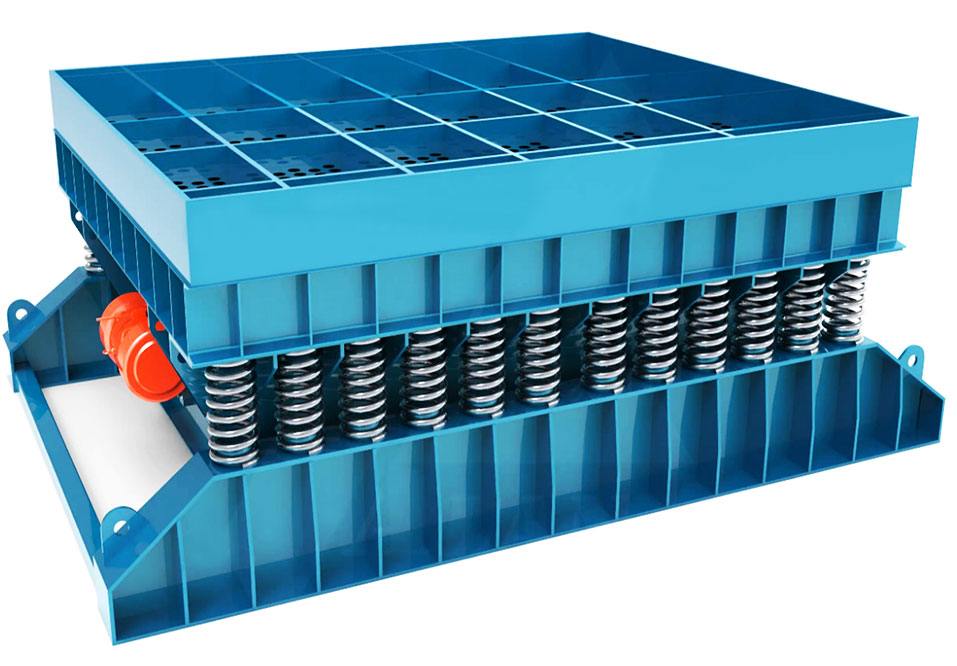

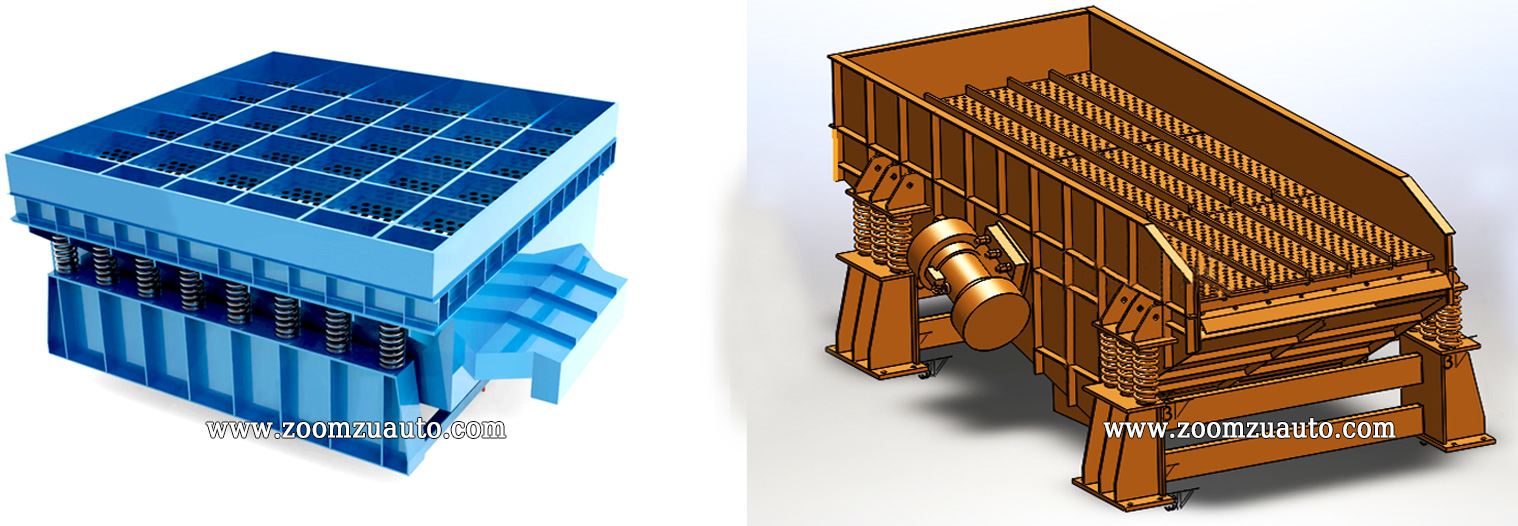

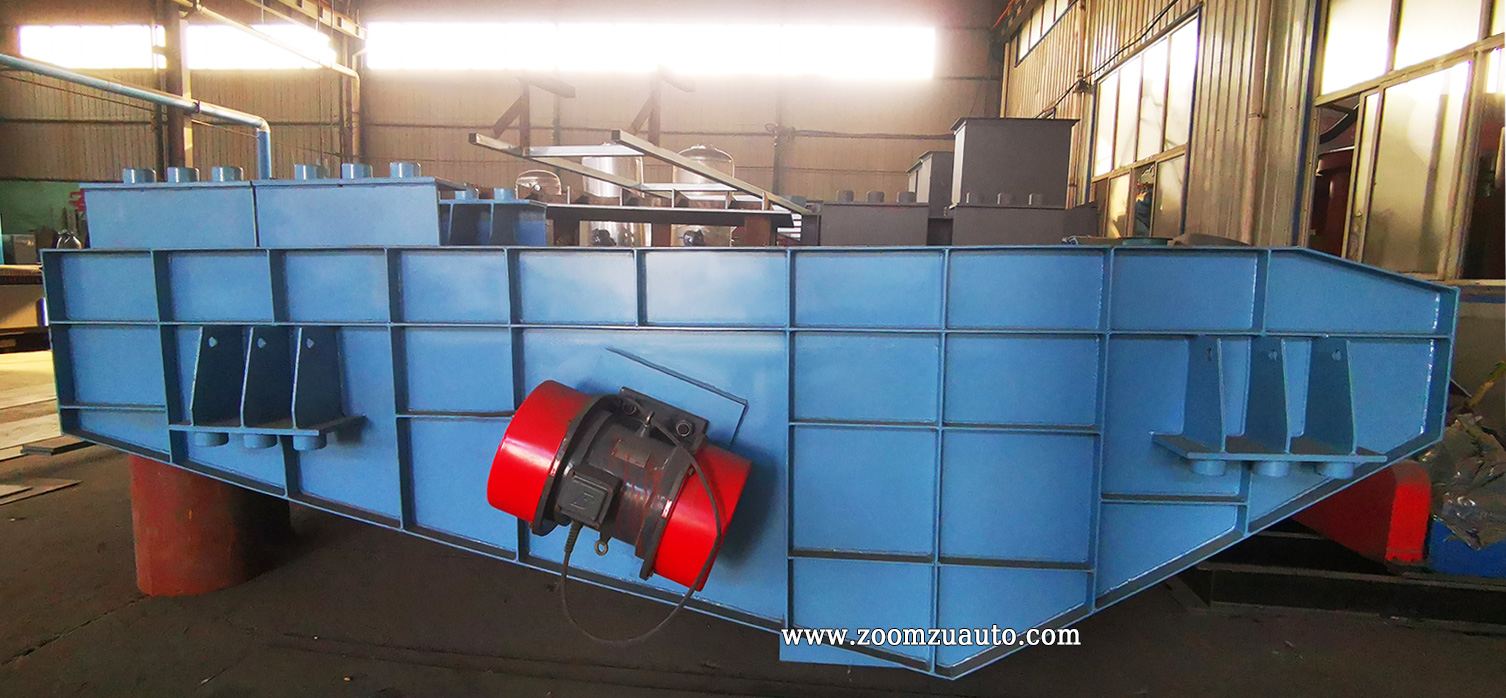

This series of vibrating screening equipment separates sand molds from castings through vibration. Internally, the vibrating screen mesh size and shape are designed based on the volume size and external structure of the casting. After entering the equipment, the casting gradually separates and falls off from the old sand during the vibration process. The old sand falls into the bottom belt through the mesh hole, and the casting and larger volume of scrap iron materials will be screened out. This vibrating screening equipment is the first link of the old sand treatment system and also the boundary between the molding department and the sand treatment department. It is used for the sand drop of high-temperature sand molds on the molding line and the transportation of castings.

1. Low usage cost, wide applicability, simple operation, simple structure, convenient installation and maintenance;

2. Different specifications of screens can be replaced according to different screening requirements;

3. Convenient installation of enclosed dust removal equipment and noise isolation;

After the sand mold is poured and cooled, we usually use a vibration sand blasting machine to separate the sand and castings, and break and recycle the casting sand. The most commonly used vibration sand blasting machines in the casting sand treatment system are mainly divided into fixed side discharge vibration sand blasting machines and conveying bottom discharge vibration sand blasting machines;

The vibration sand blasting machine utilizes the combination of inertial and elastic forces generated by vibration excitation. The installed vibration motor runs in reverse synchronization, and the horizontal component forces maintain mutual balance. The combined force in the vertical direction causes the isolation body of the sand blasting machine to vibrate sine at a certain acceleration or frequency with the same working mass. There is a certain gap between the inner wall of the body and the grid bed, which is driven to vibrate up, down, left and right by the rotation of the eccentric block of the vibration motor. When the cooled sand mold falls on the vibrating grid bed after pouring, the vibration generated can effectively impact and break the sand mold, and maintain high-frequency vibration to fully remove most of the sticky sand on the casting, thus completing the sand drop process of the casting.

In the matching of horizontal parting molding production lines, conveyor type bottom discharge material vibration sand drop is also commonly used. Its main function is that when the casting and old casting sand are separated under the excitation force, the casting is transported along a designated direction on the inclined vibration grid network until it falls into the container or scale conveyor for collecting the casting.

The installation position of the conveying vibration sand drop needs to consider whether it is convenient for the casting to be picked up and the path for the recovery of old sand, and make good ground foundation and reinforcement. The vibrating sand blasting grid mesh will be designed with appropriate screen mesh based on the shape and size of the casting, while the overall width and length of the sand blasting machine are determined by the size and weight of the sand mold.

The device is manufactured into a grid like frame using thickened anti brittle steel plates with excellent dynamic load performance, and has undergone annealing process. It has high seismic performance, reliability, and stability, and has good sand drop effect. The structure of the equipment is simple and the investment cost is low, making it an ideal vibrating sand blasting machine at present. This equipment will be equipped with dust removal equipment and undergo corresponding sealing and sound insulation treatment during installation, so it is also a casting equipment that can actively respond to environmentally friendly and green production.