-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

We have equipped three automated casting and molding production lines for three cookware casting enterprises in Zhejiang, Hunan, and Hebei provinces in China, as well as five casting enterprises in three countries including Pakistan, Malaysia, and Vietnam, providing casting and molding machines. These machines have also been applied in the automated casting and molding production of cast iron cookware castings;

The automatic casting molding machine for cast iron pots has a molding effect on the lower and upper sand boxes of the sand mold, with a molding speed of about 80-92 molds per hour;

In the automated casting and molding production of cookware, high requirements are placed on the surface smoothness of the cast blanks. Therefore, it is also necessary to control the quality requirements of the casting sand during the treatment and mixing process. After demolding, an air gun should be used to clean the fallen sand and gravel in the mold cavity to avoid defects such as sand holes in the casting;

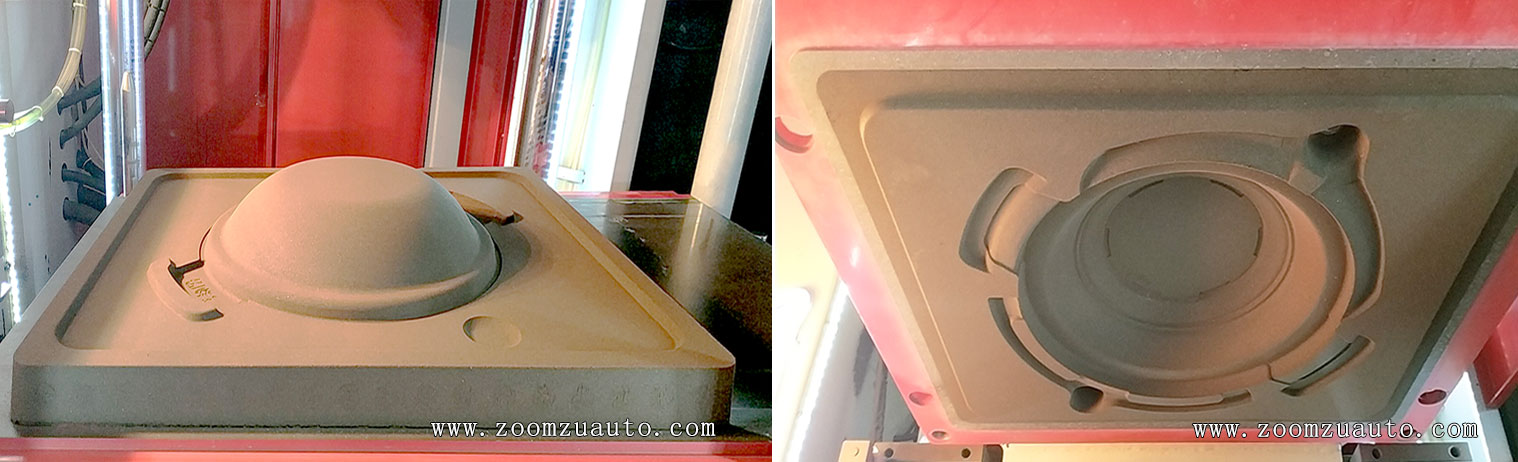

The automated casting molding effect of cast iron flat bottomed pots;

The automated casting molding effect of cast iron frying pans;

The automated casting molding effect of striped bottom cast iron cookware;

Various finished cookware made of cast iron materials, such as flat bottomed pots, cast iron frying pans, and cast iron baking pans, produced using automated casting and shaping equipment; If you need to know more detailed information about the use of cooking utensils casting equipment, you can contact us, or if you need to purchase castings from this series, you can also contact the casting company through us;