-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

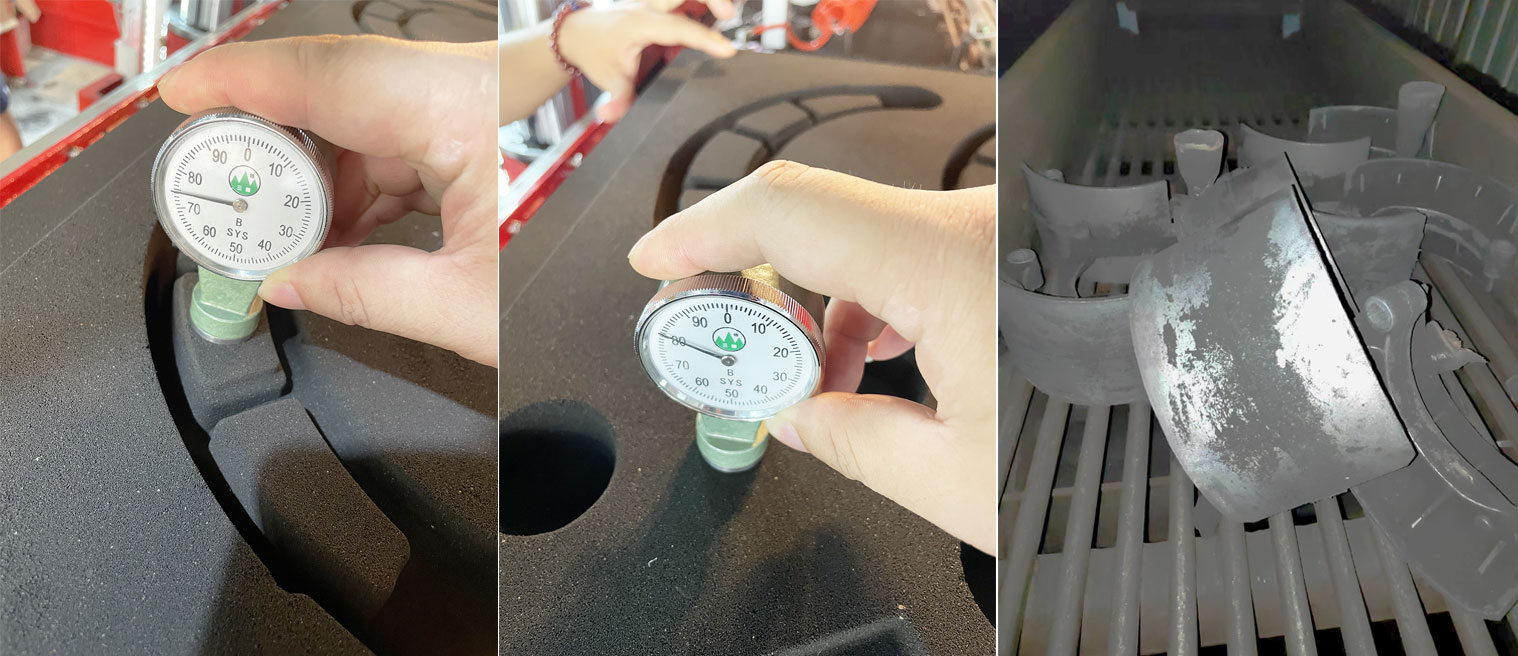

The above picture shows the molding effect of using a horizontal parting automated casting molding machine to produce brake shoe castings. The sand shooting type of the molding machine is double sand shooting cylinder horizontal sand shooting, with a molding speed of 50 sand molds per hour. Each sand mold is used to cast 8 brake shoe castings.

The size of the sand mold is 1000mm-850mm. When the main pressure of the molding machine is 600 megapascals and the sand mold is compacted, the compactness of the sand mold in the cavity of the sand mold that separates from the test after compaction is 75-83. However, in actual production casting, the sand mold with the size of 1000mm-850mm requires two pouring workers to pour simultaneously on both sides of the sand mold, and an exhaust hole connected to the molten iron is reserved in the middle of the sand mold;

The workers in the casting workshop are knocking on the sprue and polishing the cleaned brake shoe castings, as well as displaying the complete brake shoe castings. For this type of casting, automated casting molding is used for production, and the mold shape is complex and has certain modeling difficulties. Therefore, the requirements for the required sand during molding are relatively strict. Only by providing high-quality casting sand for the molding host can the overall batch yield of castings be controlled well;