-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

In June 2019, Zoomzu provided a 510mm x 610mm automated sand molding machine for a gearbox housing foundry to meet the automated production needs of various types and sizes of gearbox housings. In September 2022, the foundry collaborated with us again to purchase a new automated sand molding production line with a sand mold size of 610mm x 710mm. Based on the customer's casting size requirements, a horizontal-parting automated sand molding machine was paired with a horizontal automated production line. This setup enables the automated molding of larger gearbox housings, along with automatic nesting frames for sand molds and automated lifting and placement of counterweights, making the casting process more efficient and reducing manual labor for workers;

The automated casting production line has a total length of 47 meters and consists of 125 sand mold carts. Based on the melting efficiency of the electric furnace, which is 1.2 tons per hour, and the weight range of molten metal that can be poured into each sand mold, 38 sand mold cart workstations are arranged in the pouring section of the production line. Additionally, a high-temperature-resistant sand mold cooling belt is installed beneath the pouring platform to extend the cooling time after pouring, ensuring that the cooling duration for castings of various sizes is controlled within approximately 90 to 120 minutes;

In the automatic molding of sand molds, horizontal parting automated casting molding machines have an advantage in the production process of castings that require core placement. Users first create resin-bonded sand cores using a core shooter and wait for them to cool. The resin-bonded sand cores are then placed into the sand mold cavity of the automated molding machine, where the machine automatically merges the sand mold. Since the gearbox housing models and sizes vary, each sand mold can complete the automatic molding of 1 to 2 housing castings. Therefore, the molding speed for each sand mold ranges from approximately 45 to 62 per hour;

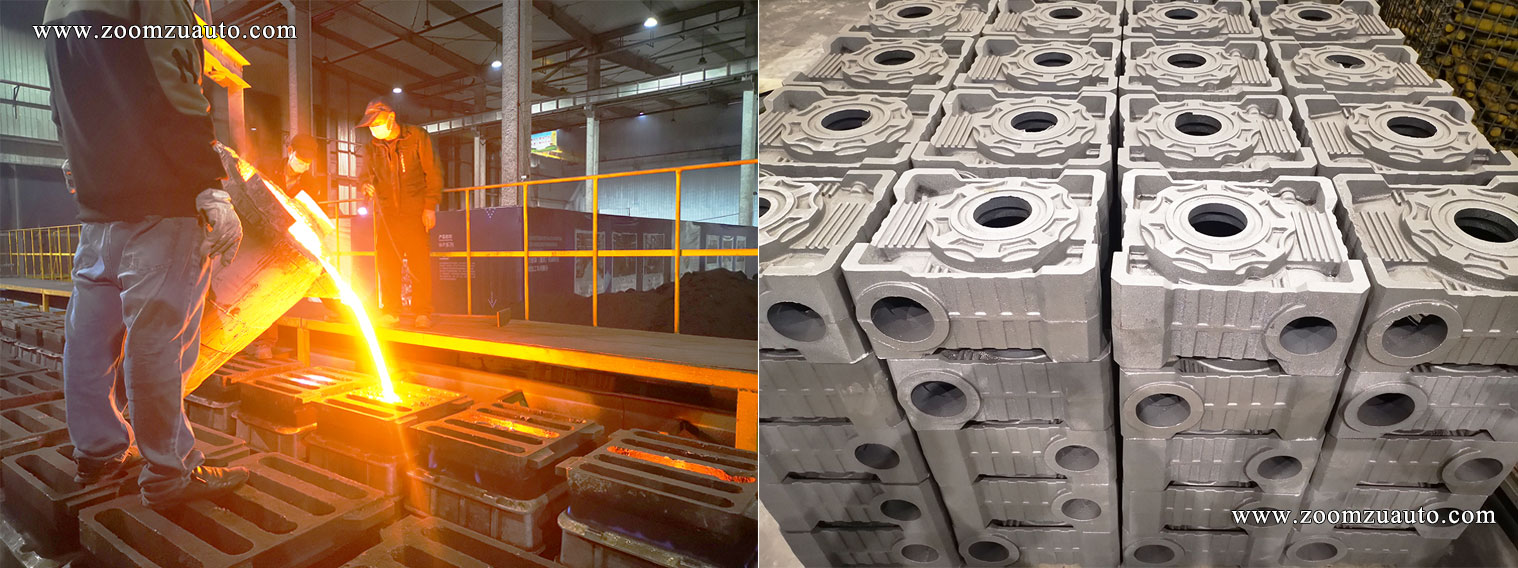

During the low peak period of electricity consumption at night, it is the busy time for casting workers. When the molten iron begins to melt, the workers on the production line will start the automated casting production line, cooperate with the melting workers to complete the molding of a certain number of sand molds through the automatic molding machine within the predetermined time and push them to the production line. At the same time, the melting workers use a crane to transfer the sand molds through the molten iron lifting bag, and repeat the operation until the next morning; The above are the pouring images of the automated casting production line and photos of the gearbox housing castings obtained after casting production.