-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

On the eve of Christmas in 2026, we completed the installation and commissioning of an automated casting and molding production line in Russia, using clay sand (green sand) casting technology for the automated casting and molding production of ductile iron sewer cover plates (grates) castings. This time, we designed and matched all the necessary equipment for the casting enterprise users, including an automated casting sand processing line, an automated casting and molding machine, an automated casting pouring line, an automated pouring machine, a melting electric furnace, a shot blasting machine, as well as equipment such as a ladle and a drying machine required for the pouring process;

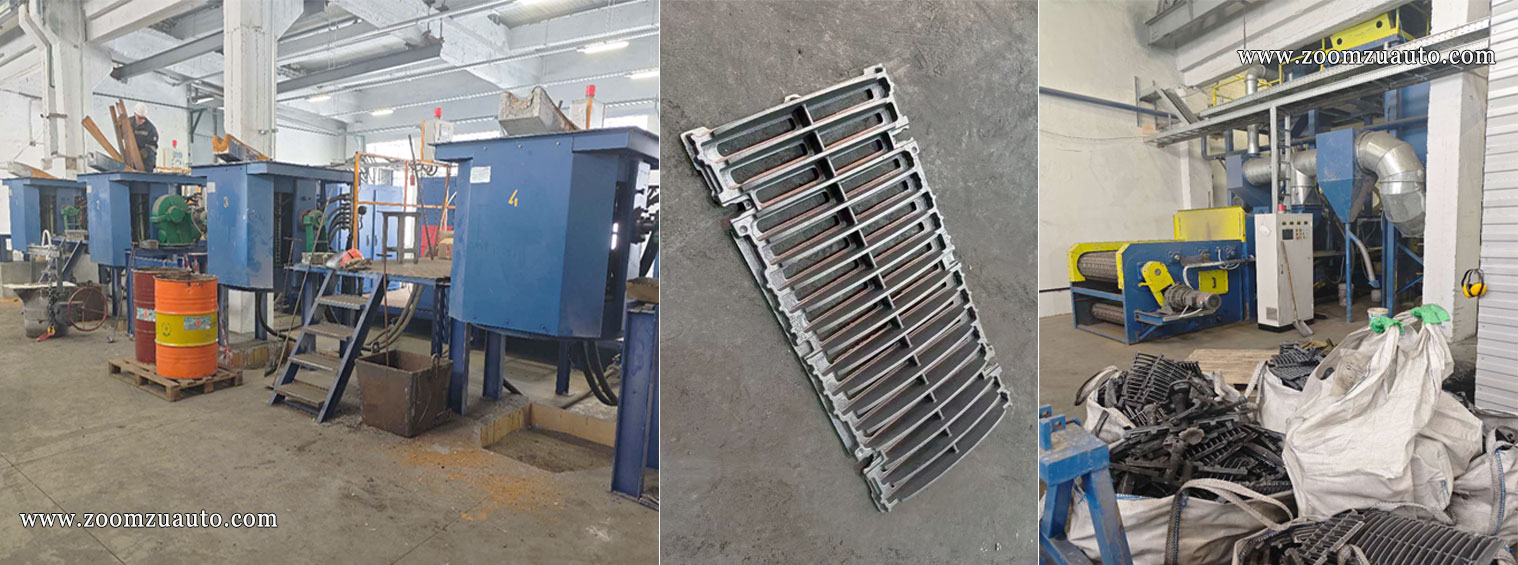

The casting sand processing equipment of this automated casting molding line is designed with a processing capacity of 40 tons per hour, mainly used for the recovery, storage, and mixing of old sand and new sand. This includes the processes of crushing old sand molds, magnetic separation, transportation, screening, cooling, dust removal, secondary screening, storage, automated water addition and feeding, and sand mixing and stirring; According to the design of a workshop at a height of 13 meters, the storage capacity of old sand is a total of 120 tons in two 60 ton sand warehouses.

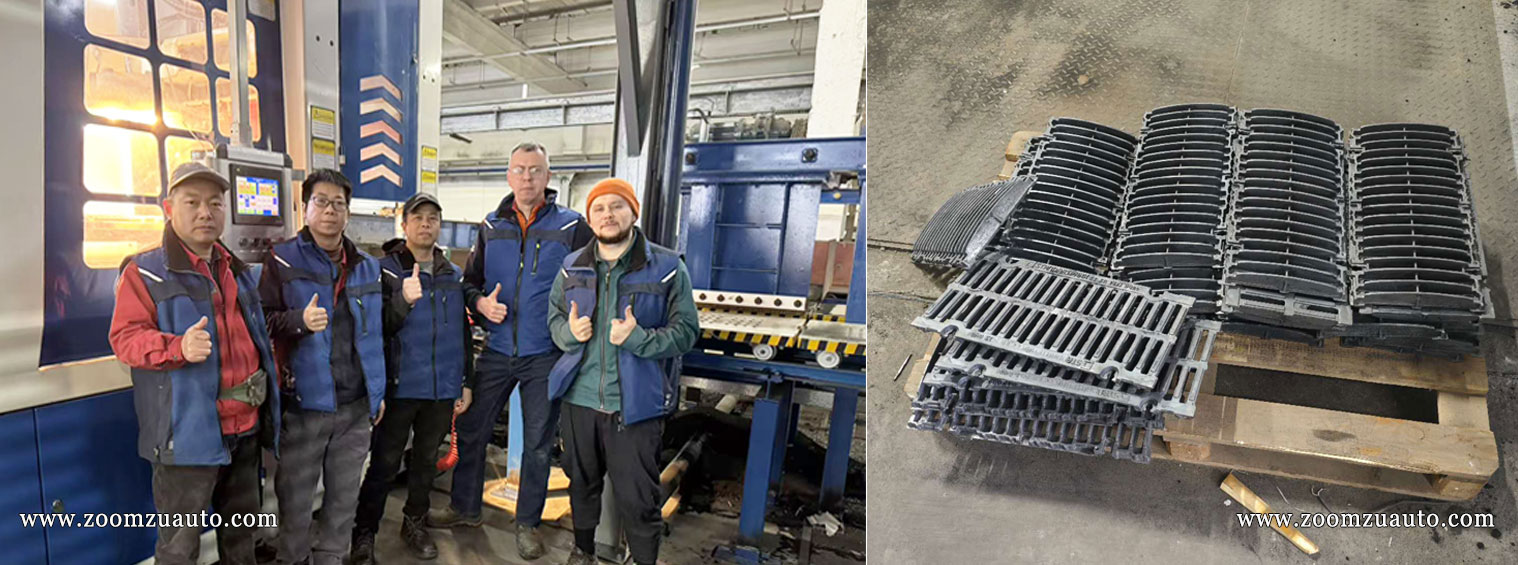

In terms of the automatic molding speed of sand molds in the casting molding line, we need to complete the molding of 120-150 sand molds per hour according to customer requirements. Therefore, we have equipped two 550mm X 650mm fully automatic casting molding machines with an automated pouring line, which not only meets the molding speed but also has one molding host as a backup; On the automated pouring line, we have equipped a total of 127 sand mold trolleys for carrying, conveying, pouring, transporting, and cooling the sand molds. Considering that the equipment's usage area may experience low temperatures, we use servo electric cylinders to make automated mechanical arms as the conversion mechanism for the iron in the sand mold box press. A high-temperature resistant cooling belt is connected at the end of the pouring line to extend the cooling time of the sand molds and castings. The cooling time for castings with relatively thin structures is about 60 minutes;

The casting of the sand mold is carried out using an automated casting machine with a metal iron liquid capacity of 500kg. After the automated casting molding machine completes the molding of the sand mold, the casting machine can automatically pour the sand mold through parameters such as the set water outlet distance. At the same time, it can maintain the same displacement according to the pushing distance and speed of the small car pushing the oil cylinder on the casting line, so that the sand mold can be continuously poured during the pushing process. The casting worker can also control the operation of the casting machine to pour the sand mold.

On the smelting unit, we have equipped four 0.5 ton intermediate frequency smelting electric furnaces based on the user's needs and the weight of individual castings, combined with the speed of sand mold automatic molding. Under normal working conditions, three intermediate frequency smelting electric furnaces are started in series, while the remaining one is used as a backup electric furnace according to the user's requirements;

We have customized a through type shot blasting machine based on the size of the castings for cleaning and shot blasting the rough castings produced every day;

After the installation and debugging of the overall automated casting molding line, our ZOOMZU debugging technicians took a photo with the technical leader of the casting enterprise, as well as photos of the finished castings after debugging.