-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

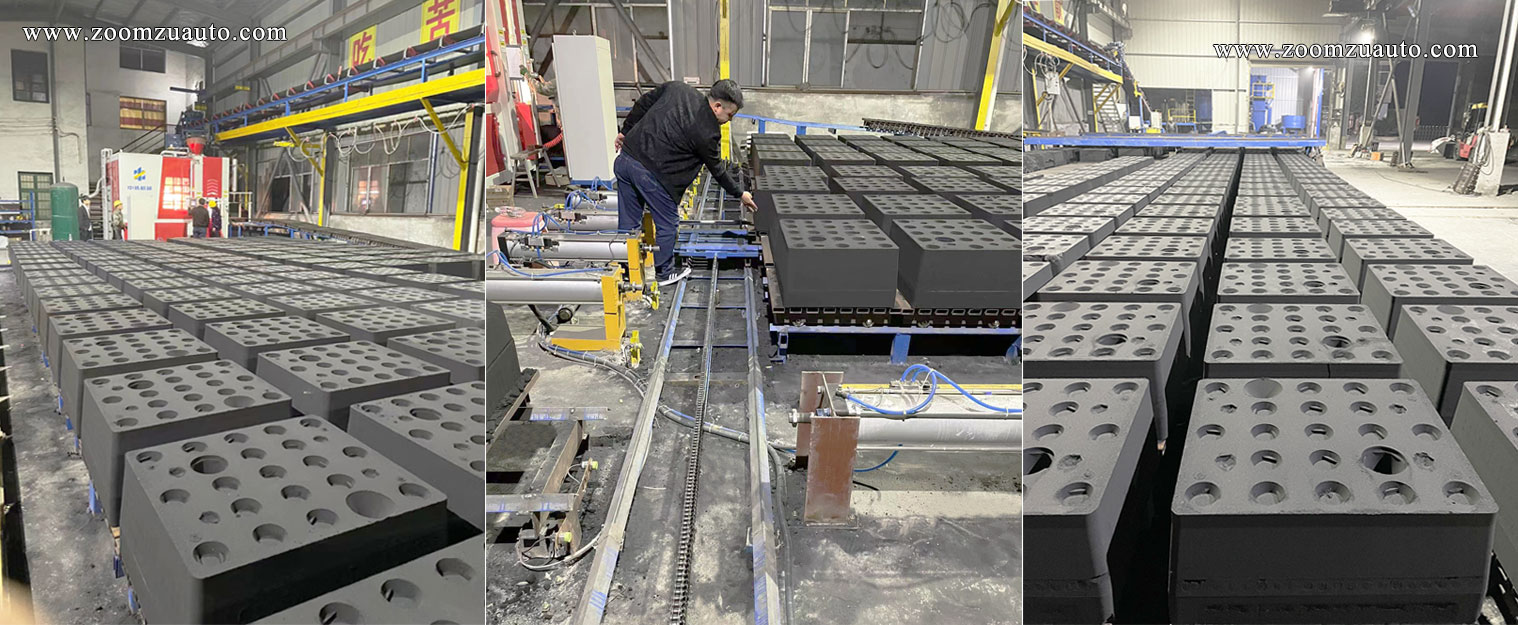

In November 2021, we provided an automated foundry molding machine with a sand mold size of 550mm X 650mm for an electric tricycle brake pot foundry, equipped with a casting sand mixing processing line and sand mold conveyor line with a processing capacity of 25T per hour; Automated molding of sand molds is carried out by an automated foundry molding machine, and the sand molds are pushed out onto transfer carts. Then, the carts loaded with sand molds are pushed onto specific tracks through automated conveyor lines and neatly arranged for pouring work;

Automated casting molding of brake pans using sand molds using automated foundry molding machines; Using a 40mm diameter pouring rod as the pouring port for molten metal, and a 30mm diameter pouring rod as the pouring exhaust hole for the sand mold cavity on the other side of the pouring channel, the weight of the casting is relatively light and the wall thickness is thin, resulting in a short cooling time. Therefore, after designing the exhaust of the sand mold, this type of casting does not require the nesting of the sand mold frame and the placement of heavy iron during the sand mold pouring process;

During the low electricity peak period at night, workers will use automated foundry molding machines to mold sand molds, while melting workers will melt molten metal and iron, and synchronously cooperate with the molding machine's molding work to pour sand molds until the next morning; In terms of pouring, in order to make it more convenient for pouring workers to complete the pouring work, we have installed parallel movable track cranes on the sand mold conveyor line, which also saves the space occupied by sand mold placement in the casting workshop; The material of this type of brake pan casting is mainly HT250, and through the use of an automated foundry molding machine, 96 sand molds can be automatically molded per hour;