-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

In June 2020, Zoomzu reached a cooperation agreement with Lonsin Machinery Equipment Co., Ltd, a professional manufacturer of breeding equipment, to build two automated casting and molding lines. They were installed and put into casting production in October 2020 for the automated casting and molding production of cast iron bottom plates and cast iron leakage plates for animal husbandry breeding beds; One of the automated casting molding lines has a sand mold size of 800mm X 1450mm, with an adjustable height range of 180mm-380mm. It is also equipped with an automated trolley to transport the casting line, which can automatically transport the sand mold and place the outer frame and weight iron of the sand mold. The sand mold size of another automated casting molding line is 550mm X 650mm, and the sand mold height can be adjusted within the range of 200mm-400mm. It is equipped with a track type conveying pouring line for producing small-sized and lightweight castings;

In terms of casting sand treatment, we have equipped two casting molding lines with an automated casting sand treatment production line that can process 60T of casting sand per hour. We provide casting sand suitable for sand mold molding for the two molding machines. After the sand mold is poured and cooled, the old casting sand is sorted by a vibrating screen and recycled back to the automated casting sand treatment production line through a belt, forming a complete set of automated casting production lines, making the entire casting molding, pouring cooling, and sand mixing more efficient and convenient;

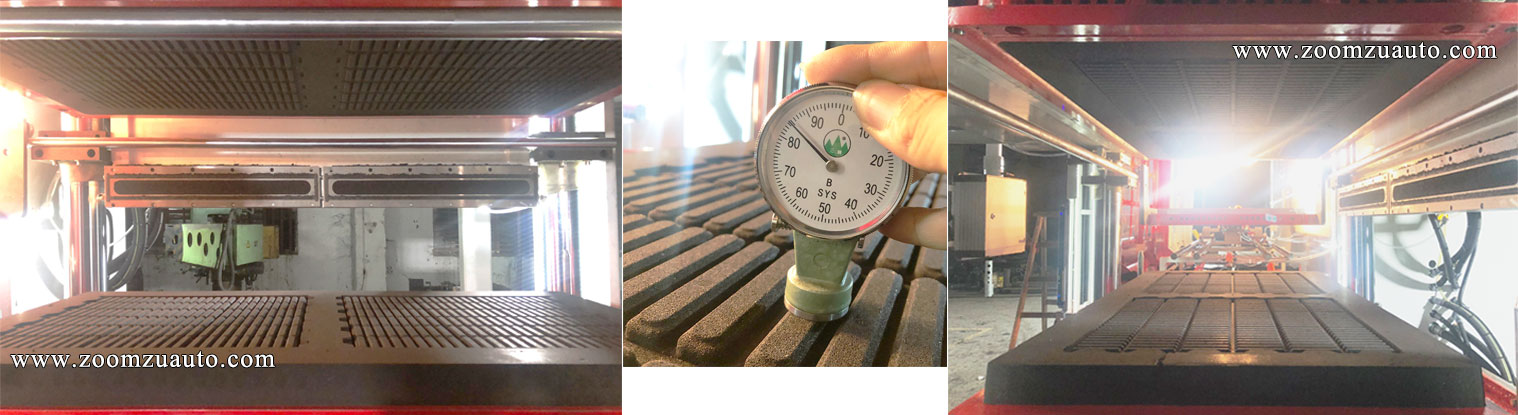

According to the user's requirements, we designed a large-sized sand mold automated casting molding machine with 800mm X 1450mm and arranged two castings according to one sand mold. After debugging and delivery for use, the compactness of the sand mold was controlled at around 85; This machine can complete 45 automated casting molds per hour;

In terms of pouring sand molds, the sand mold with a size of 800mm X 1450mm is manually poured. Due to the casting being made of ductile iron and the weight of molten iron in each sand mold being relatively high, an outer frame and weight iron need to be placed outside the sand mold during pouring to prevent expansion and cracking of the sand mold. At the same time, the structure of the casting is thin, the cooling time is short, and the horizontal area is large. To ensure the yield of the casting, two workers need to pour molten iron into the sand mold at the same time during pouring; On the contrary, the 550mm X 650mm sand mold is much simpler for producing smaller cast iron base plates and cast iron leakage plate castings. Only one pouring worker is needed to quickly pour the sand mold without placing heavy iron or sand mold frame;

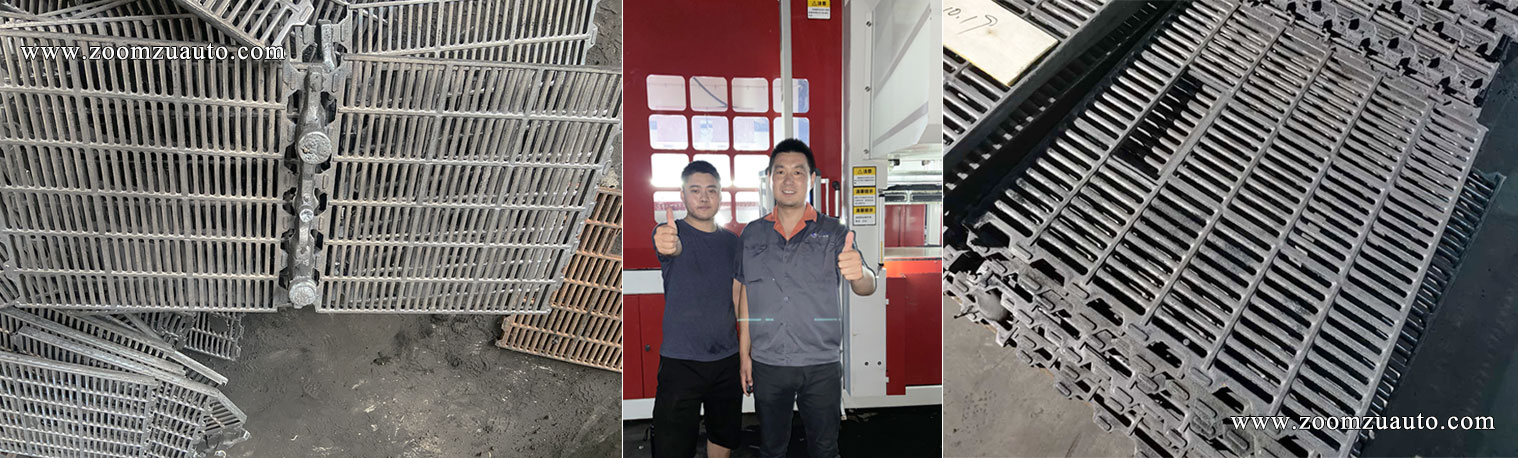

The above is the rough embryo of the casting of the leakage plate of the ductile iron breeding bed produced by the large-sized sand mold automated casting molding machine. The size of this type of casting is 600mm X 700mm; After four months of installation and debugging, we also gained recognition from our customers;