-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

In November 2024, ZOOMZU reached a cooperation agreement with a company that produces compressor parts through casting. In January 2025, a set of automated casting molding lines with a processing capacity of 30T per hour of casting sand mixing equipment will be delivered, and the installation of the overall equipment will be completed. The casting molding line will be equipped with a fully automatic horizontal parting molding machine with a sand box size of 700mm X 700mm (length x width) and an automated pouring line. The sand mold cooling belt will be connected at the end of the pouring line; This automatic molding line is divided into two rows of pouring sections and one row of cooling sections. During operation, the two rows of pouring sections can be used interchangeably, and the molding of the main machine and the pouring of the sand mold do not affect each other. After the sand mold is poured, the cooling time until the tail sand mold enters the sand dropping machine can be controlled within the range of 90-120 minutes;

In the early stage, manual pouring was used. After the equipment was put into normal operation, the user installed a pouring bag crane track above the molding line, which is planned to assist workshop personnel in pouring sand mold models more conveniently;

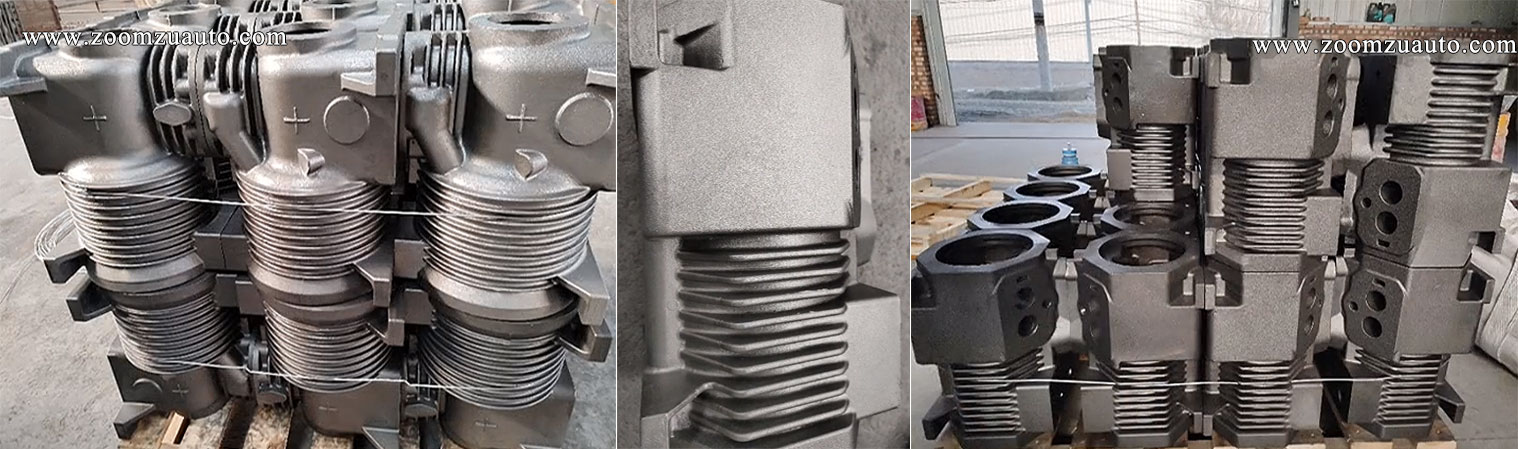

The model of the automatic molding host is a horizontal parting molding machine with top sandblasting and bottom sandblasting. This sandblasting method can better complete the filling of complex types of molding sand such as compressor shells, and the horizontal parting method combined with the selective sliding out of the sand box brings more convenience to the placement of coated sand. Each sand mold is designed to discharge one casting and flanges for cavity exhaust are reserved on both sides of the sand mold; The above picture shows the placement of the laminated sand core and the demolding of the lower sand box;

The compressor casing castings produced using an automated casting molding line have received feedback from users that the yield rate is more guaranteed compared to manual molding, and the overall smoothness of the castings is high. There is a significant improvement in the quality of the castings, and users no longer need to worry about the aging and difficulty in recruiting molding workers;