-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

This is a small agricultural machinery parts casting production enterprise, mainly providing raw castings of cast iron material for local agricultural machinery equipment manufacturers. In March 2020, the casting enterprise expanded its green sand casting workshop and introduced automated casting equipment to improve casting capacity and shorten the production cycle of castings. During this period, we designed and assembled a set of automated casting sand mixing and processing equipment with a processing capacity of 30 tons per hour for the enterprise, matched with a conventional automated horizontal parting molding machine with a sand mold size of 510mm X 610mm, which is used for automated casting production of some agricultural machinery castings with high demand;

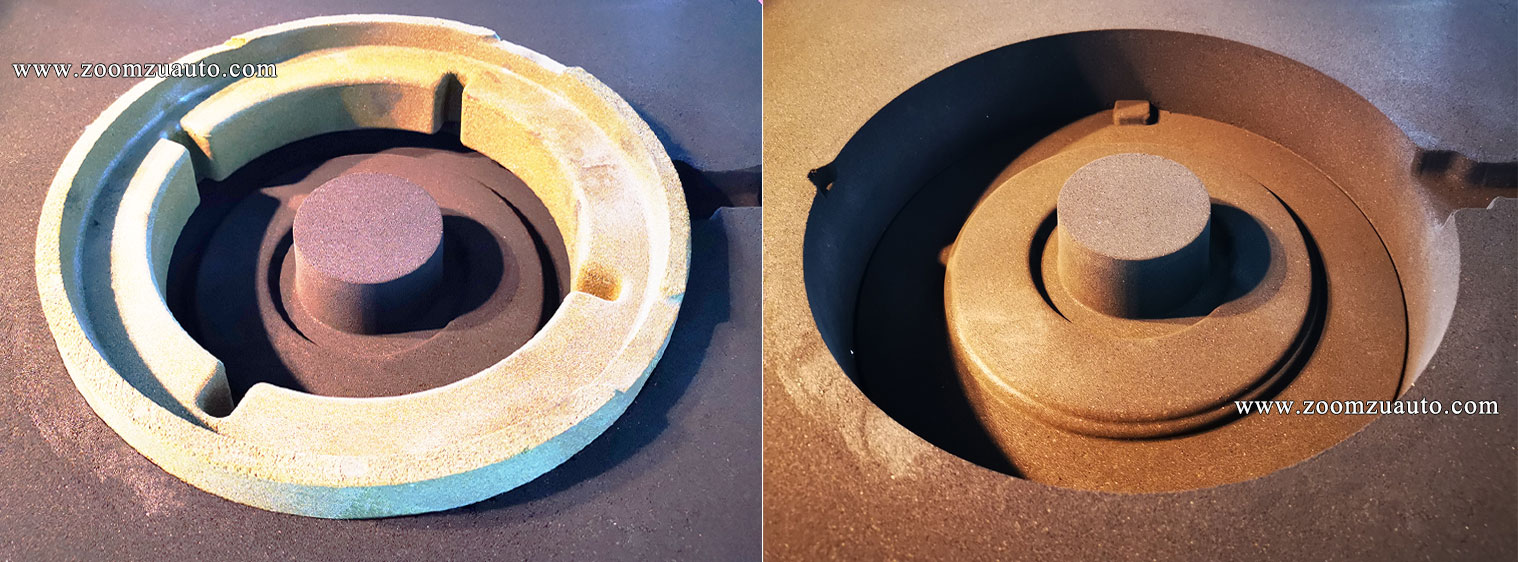

Use an automated casting molding machine to shape the outer shell wheel body of the reducer. The picture shows the molding effect of the sand cavity in the upper sand box and the corresponding mold photo;

For some castings with complex shapes, coated sand is placed as the core. The above picture shows the cavity effect of the sand box under the automated molding machine after compaction and mold detachment;

During the day, workers in the workshop use automated casting equipment to mix molding sand and perform automated molding of sand molds. The molded sand molds are placed flat on the workshop floor, and at night, smelting workers pour molten metal into the sand molds to complete the casting production of castings with clear division of labor and avoid peak electricity consumption periods; The photo was taken in May 2021 for user follow-up and equipment maintenance. The company also retains some traditional manual sand casting techniques to meet the production needs of small batch casting;