-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

This is a green sand casting automation molding machine with a sand mold size of 610mm x 610mm (L X W) customized according to the requirements of the casting enterprise. The height of the sand mold can be adjusted according to the production requirements of the casting, and the height range of the sand mold is 300mm-500mm; Two sand cylinders are used to fill the sand mold by sandblasting from both sides under the pressure of airflow, and then the filled sand mold is compressed again by an oil cylinder to complete the automatic molding of the sand mold; The green sand automatic molding line will be installed and officially put into use in 2022. The pictures were taken and recorded during a follow-up visit to the user in May 2023. The production and use of the entire molding line includes mixing of molding sand, molding of sand molds, pouring of sand molds, and melting of molten metal, with a total of 5 people; The hourly sand mold size is 70-80, mainly used for the casting production of clutch castings.

The enterprise has three green sand casting molding lines of this type and one multi contact static pressure molding line, of which two green sand molding lines were later renovated and replaced with outdated automated molding machines by us.

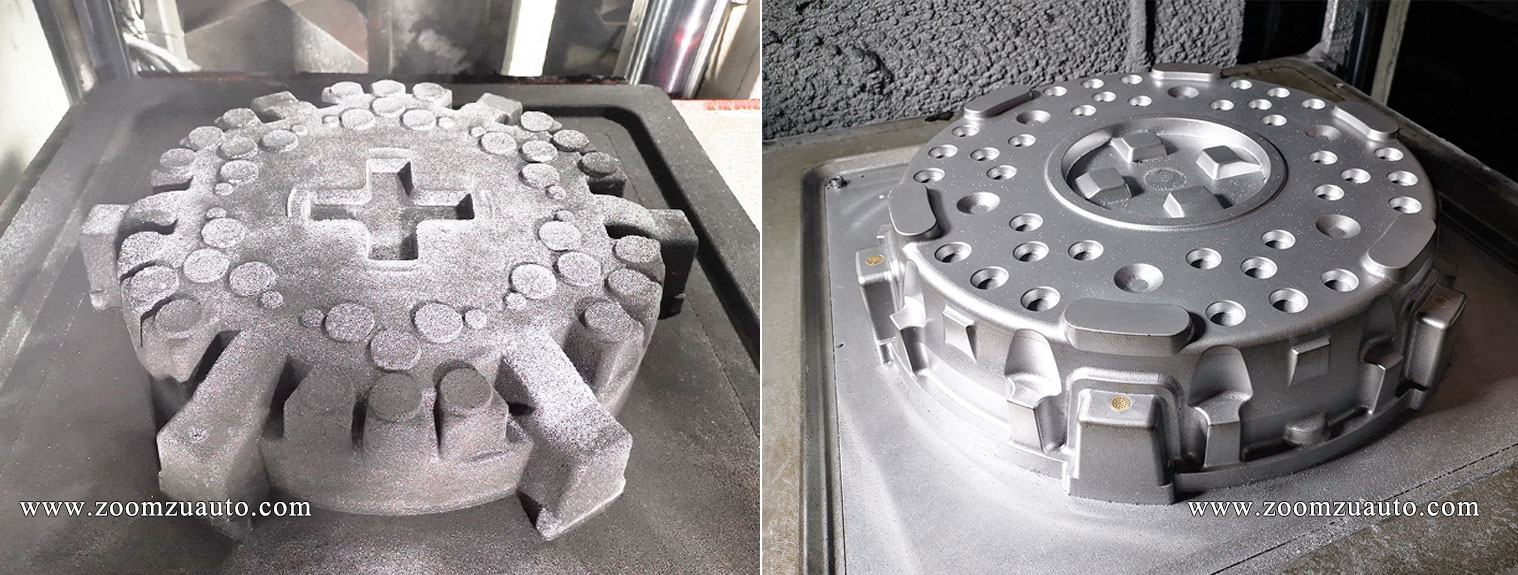

The effect picture of the automatic shaping of the clutch cover casting of the car using green sand and the corresponding mold for the casting. The user used the embedding method in the mold production, and flexibly adjusted the size of the mold template according to the different sizes of the sand box, so that each set of molds can be used on green sand molding machines with different sand box sizes;

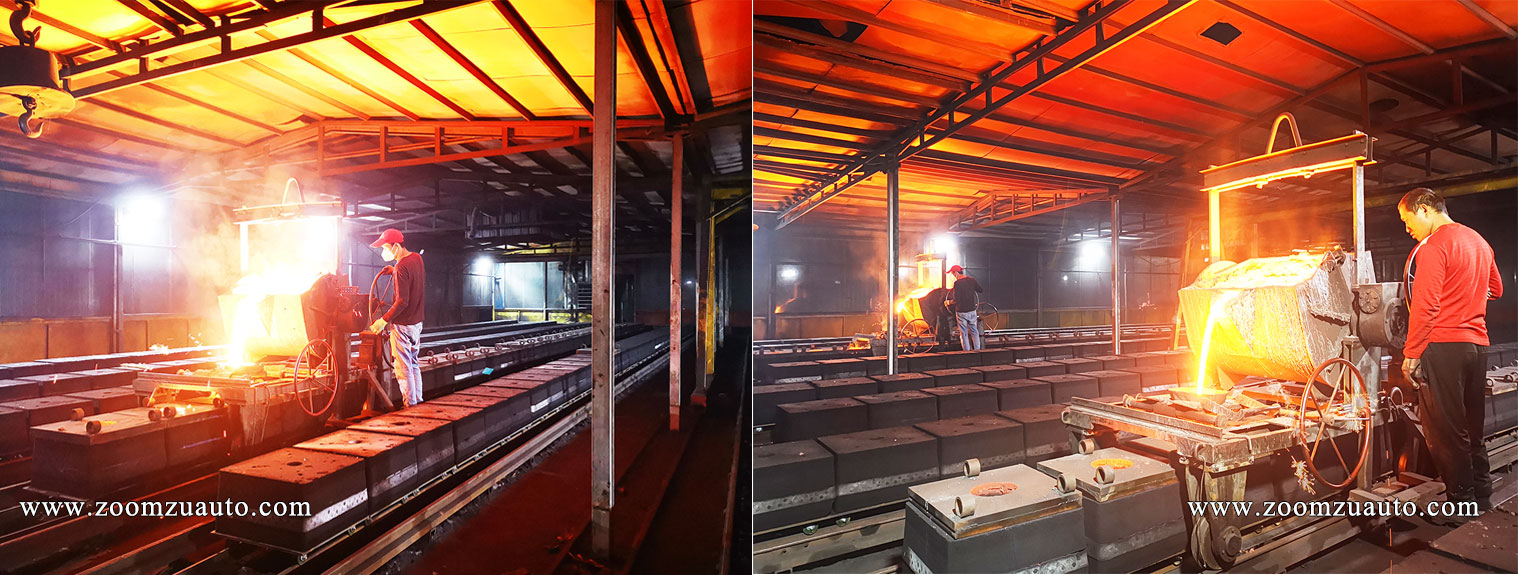

This is a pouring line that uses ground laid tracks to transport sand molds, and the user has self-made a semi-automatic pouring cart. Overall, this design of semi-automatic pouring cart is very practical and reliable in the actual production and casting process;

After using a shot blasting machine to clean the rough blanks of various specifications and models of clutch castings on the surface of the castings, the user has very professional casting technology and uses an automated casting molding production line to produce this type of clutch casting. The casting yield is controlled at around 98%; These rough castings after shot blasting cleaning will be manually processed and assembled into complete clutch brakes.