-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

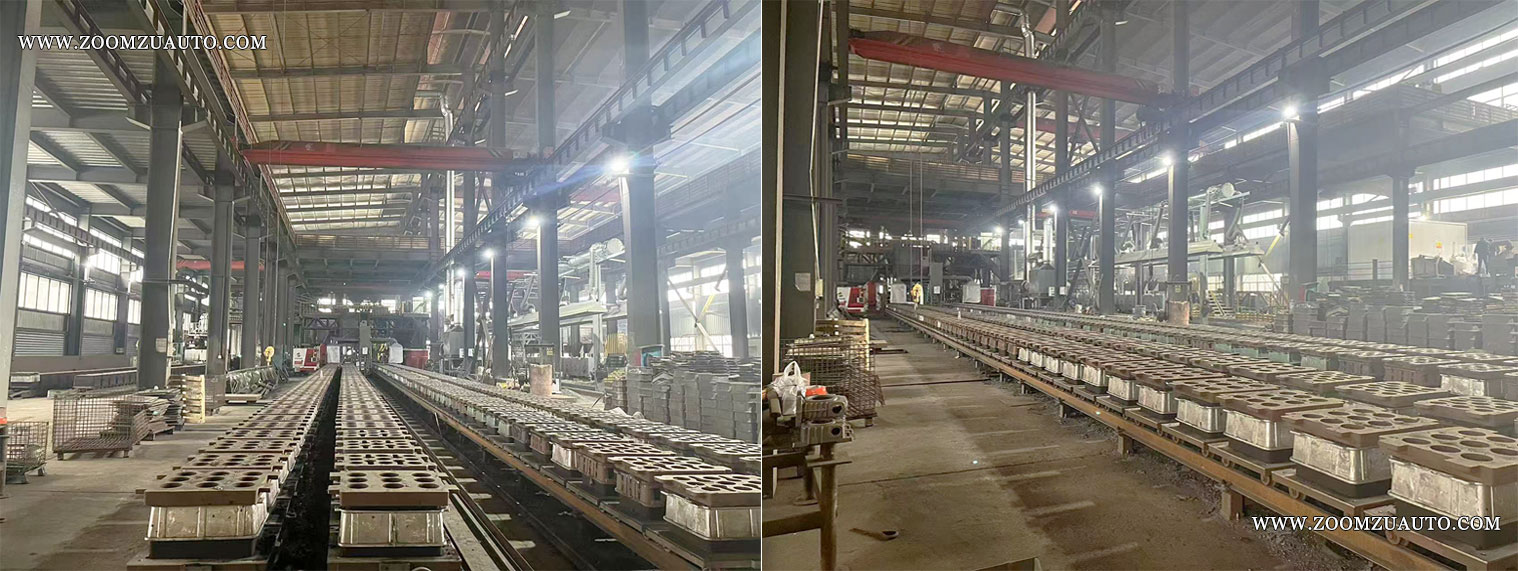

In March 2021, we provided an automated casting and molding production line for an enterprise that produces transmission parts such as turbine reducers and elevators. We upgraded and transformed its original casting workshop and connected it to the existing casting sand processing production line in the workshop. We transformed the originally cumbersome casting production process into a sand mold automated molding process, with convenient and efficient casting production processes such as automated sand crushing, cooling, and mixing; The casting workshop has a sand processing system with a processing capacity of 40 tons per hour. ZOOMZU has equipped it with two horizontal parting automated casting molding machines and two sand mold automated conveyor lines. Based on the main product casting size of the enterprise, a conventional 420mm x 520mm and a 510mm x 610mm sand box size casting molding machine have been selected, with a cooling time maintained at around 70-85 minutes. After renovation and upgrading, the casting workshop can produce 20T-25T castings per day, which can increase the casting production capacity by about 8T castings per day compared to the original casting production capacity;

For the renovation of the casting workshop of the enterprise, we spent 25 days from the determination of the plan to the installation and commissioning of the equipment. The user expressed full recognition and affirmation of the construction coordination and the final use effect of the automated casting molding line. The above is a photo of the workshop manager and commissioning personnel, as well as the molding effect of the sand mold of the transmission parts during the casting molding process;

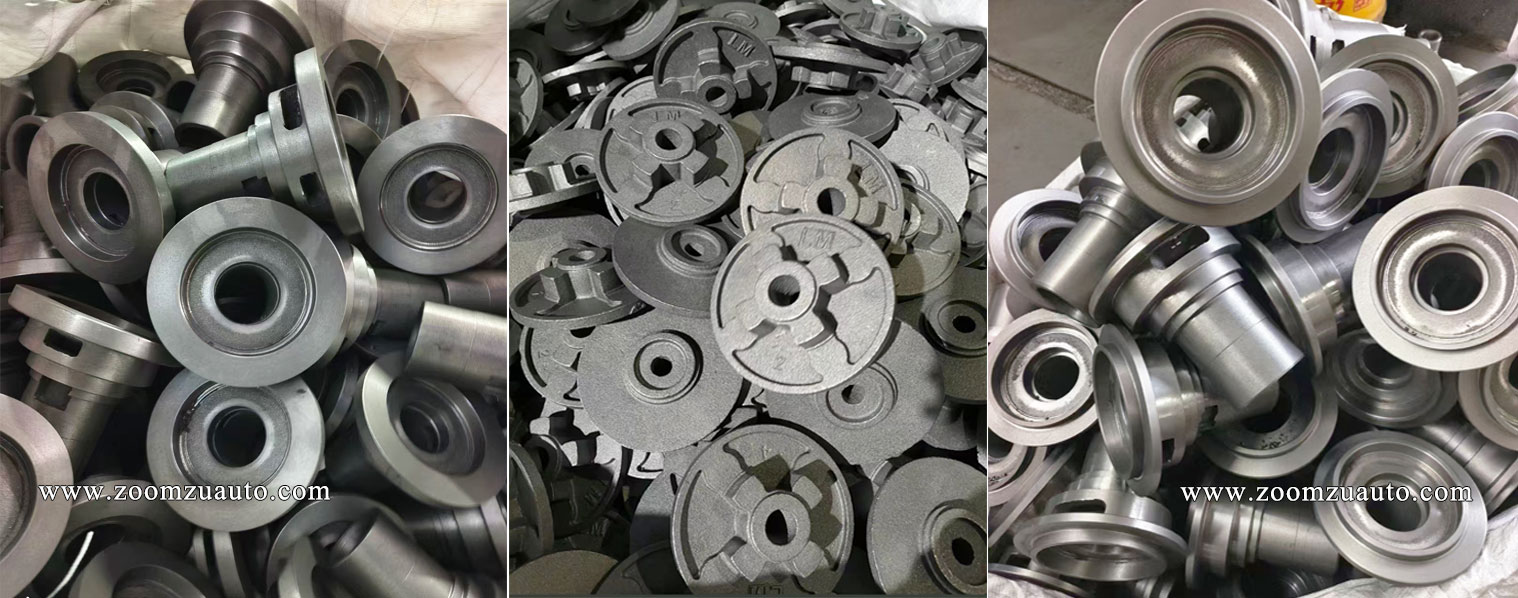

The casting effect of the transmission shaft casting made of cast iron material after processing, as well as the rough embryo effect of the semi-finished casting of the sealing cover made of cast iron material after sand cleaning and polishing, were maintained at around 98% with the active cooperation of the technical personnel of the enterprise and our debugging personnel;