-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

In March 2021, we installed and manufactured a set of tidal sand automated casting and shaping equipment for Dalian, Liaoning Province, China, mainly used in the automated casting and shaping production of automotive parts. In the casting workshop of enterprise users, some parts of the factory will be raised to 9-11 meters for the installation of automatic processing equipment for wet mold sand. The sand will be mixed with the automatic casting molding machine and transported to the small sand storage bin above the molding machine through a belt conveyor. Approximately 20 tons of casting sand can be mixed per hour; The size of the automated casting molding machine sand box is 550mm X 650mm. Most automotive parts require manual placement of coated sand cores inside the sand mold cavity during casting molding. Therefore, the actual automated casting molding speed is 50-60mold sand molds per hour, and the daily production of automotive parts castings is 8T-12T;

According to the original layout of the casting workshop of the casting enterprise, the electric furnace melting area of the original casting workshop is located on the right side of the workshop. Therefore, we have placed the automatic casting treatment equipment for wet mold sand on the far left side of the casting workshop. The mixed sand is transported to the sand storage bin by a belt conveyor, and the molding machine is customized to a left push structure according to the equipment placement, reducing the span and length of the belt conveyor and facilitating the daily operation and use of workers; The sand molds completed by automated molding machines are placed in the casting workshop, waiting for workers to uniformly pour metal iron into the sand molds at night;

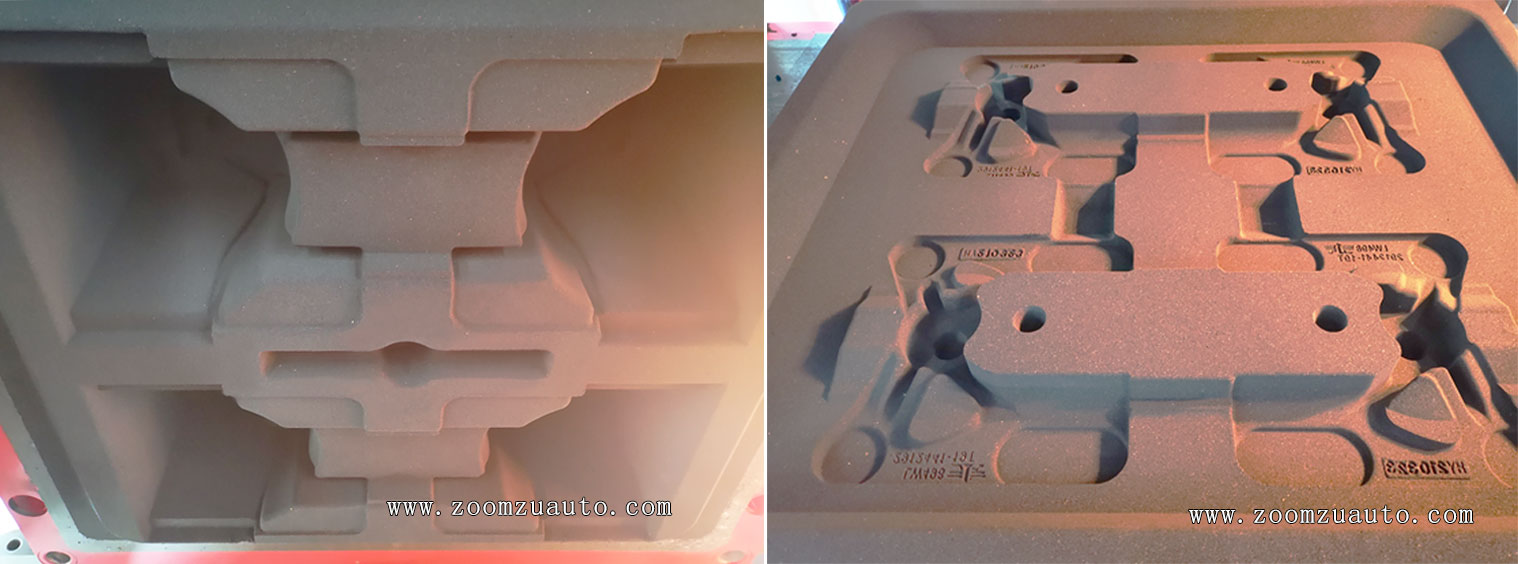

The automatic molding effect of using an automated casting molding machine on automotive steering knuckle castings. The above picture shows the cavity effect of the upper and lower sand boxes after the molding machine compacts the mold and separates it from the sand mold

Picture of the automated molding machine mold for automotive steering knuckle castings, as well as the cavity effect picture after placing the coated sand core in the lower sand box. If you need more detailed information about the use of automated casting molding equipment for automotive parts or purchasing this type of castings, you can contact us.