-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

In April 2021, we signed a cooperation agreement with a fitness equipment casting factory and provided it with a production line for wet sand casting treatment, paired with a conventional automated casting and molding host, for the automated molding production of woven belt flywheel castings for fitness equipment, replacing traditional manual molding, solving the problem of recruiting molding workers and reducing casting production costs faced by the casting factory; In June 2021, we completed the construction of the tidal sand treatment system in the user's casting workshop and the assembly of the molding host. The user visited the assembly workshop and inspected the equipment;

This enterprise is a traditional handmade family workshop small casting factory. Due to the limitation of workshop available area and budget issues in the early stage of capital investment, we have equipped the enterprise with relatively simple wet sand treatment equipment, mainly including sand mold vibration and sand falling equipment, old sand drum screening equipment, dust removal equipment, and a high-speed rotor sand mixer with a diameter of 1600mm. The local factory building is raised to 11 meters at the position of the sand mixing unit, and a storage bin is equipped to store the materials required for molding sand, which is used for automatic timing and quantitative addition of molding sand materials during molding sand mixing. This simple wet sand treatment system has a processing capacity of 20T of old sand per hour; The sand box size of the automated casting molding machine is 550mm X 650mm, and the hourly molding speed is 85 sand molds;

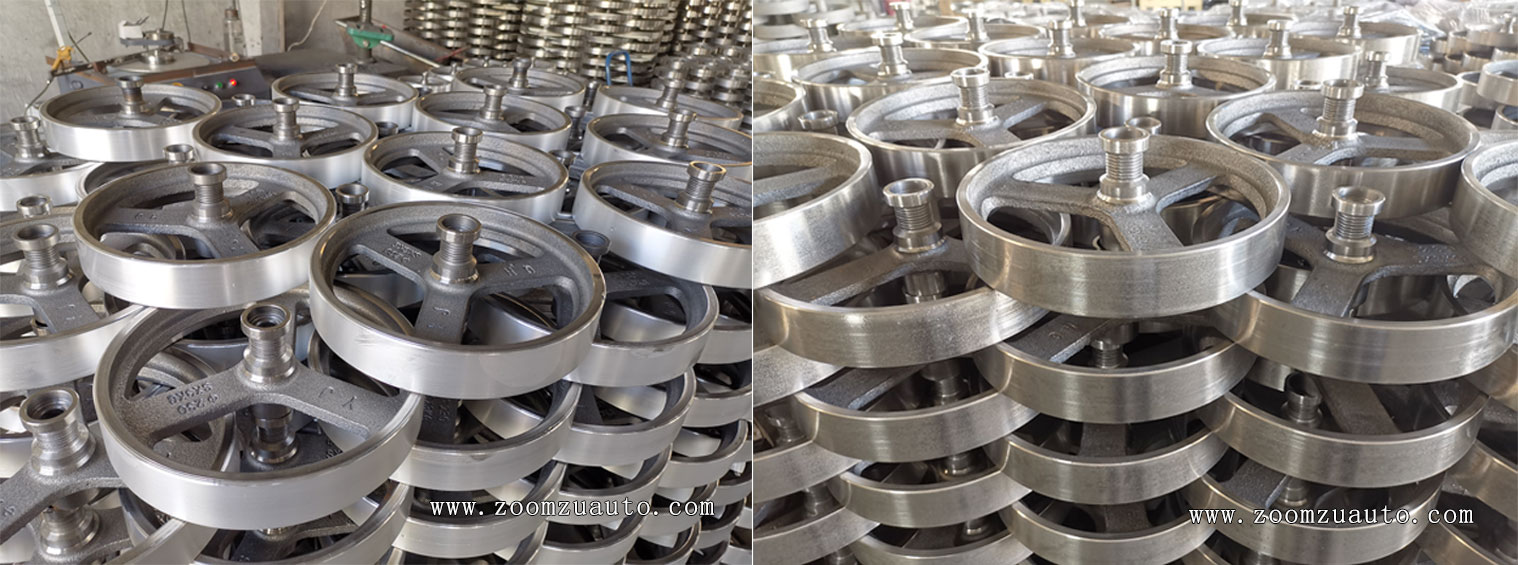

The weaving belt flywheel casting of fitness equipment is compacted by an automated casting molding machine and has a horizontal parting surface effect diagram. Each mold can complete the shape of four flywheel castings. The metal iron pouring hole is located in the middle position of the sand mold, and an exhaust hole is set outside the parting surface of the sand mold;

The casting enterprise also adopts the operation method of daytime molding and nighttime pouring. Every day, workers start to complete the molding of sand molds in batches through automated casting molding machines from the afternoon and neatly place the sand molds in the casting workshop. Until evening, another pouring worker is responsible for pouring metal iron into all sand molds. The poured sand molds will be cooled down until the next morning when the daytime workers take out the castings. After the castings are taken out, the old sand will be cooled by adding water and stacked by a forklift. The castings will be cleaned by shot blasting and sent to the CNC processing workshop for hole rotation and peripheral processing;

Compared with traditional manual casting, the castings produced by automatic casting machines are more conducive to controlling the overall casting yield and individual casting weight of the processed fitness equipment webbing flywheel castings;