-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

This is a complete set of tidal sand automated casting molding line that we have produced and installed for a casting enterprise in Shandong Province, China. The enterprise actively responds to regional environmental protection policy rectification requirements: to eliminate outdated casting capacity and casting factories with production emissions that do not meet standards. In April 2022, the workshop rectification plan was determined and automated casting equipment was purchased. The overall transformation and upgrading of the casting workshop was completed in December 2022, All equipment installation and debugging have been completed, and the entire production molding line has been put into trial operation. In January 2023, it was accepted by the local environmental protection bureau and met the prescribed emission standards, becoming a qualified enterprise to complete the rectification and upgrading of casting enterprises in a regional manner on time;

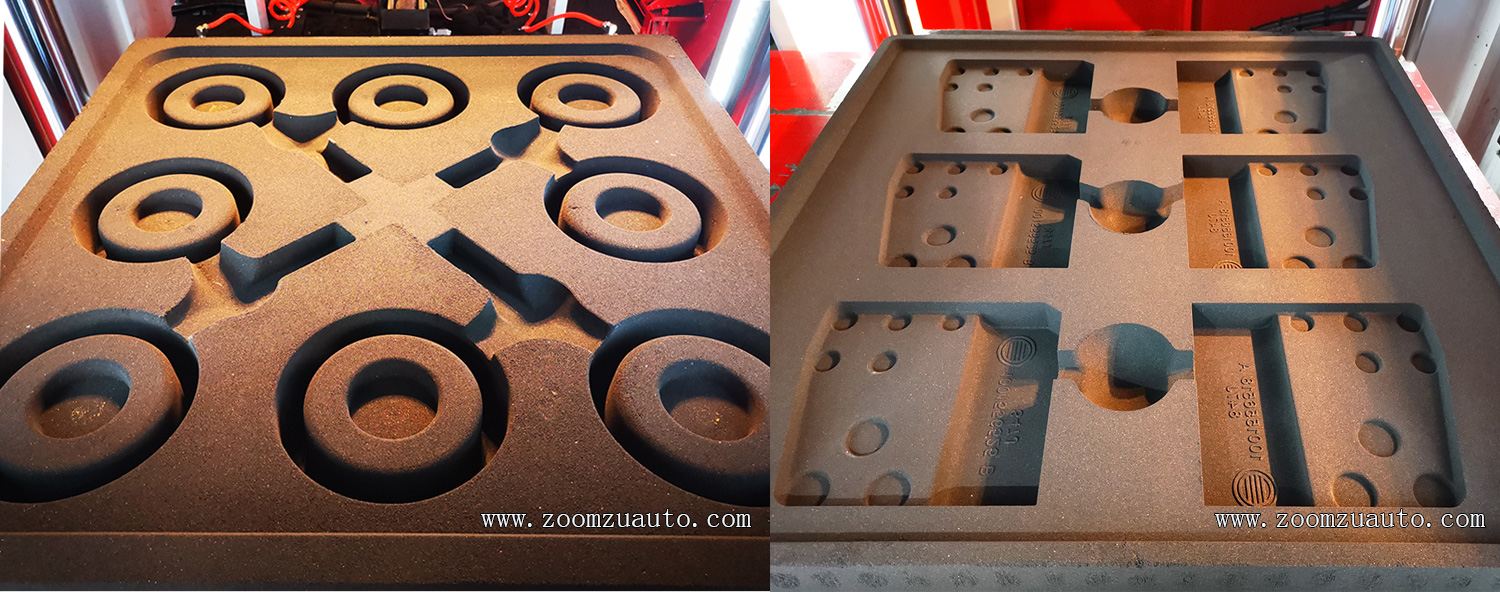

The fully automatic horizontal parting molding line for tidal sand is equipped with a dual barrel double-sided sand shooting molding machine and an automated pouring line for placing box frames and heavy iron. The size of the automatic molding machine's sand box is 750mm X 750mm, the height of the sand mold is 320mm-520mm, and the molding speed is 75 sand molds per hour. It is mainly used for casting and producing diesel engine parts made of ductile iron;

The grabbing device, conversion device, and pushing device of the automated horizontal parting pouring line adopt servo electric cylinders, and the overall molding line adopts A and B line designs, namely the pouring section and cooling section; The entire line is 45 meters long and can accommodate 42 pouring stations. It is designed based on the existing electric furnace melting speed of 1.2 tons of molten iron per hour and the iron consumption of 50KG-70KG per sand mold; The cooling time is about 45-60 minutes;

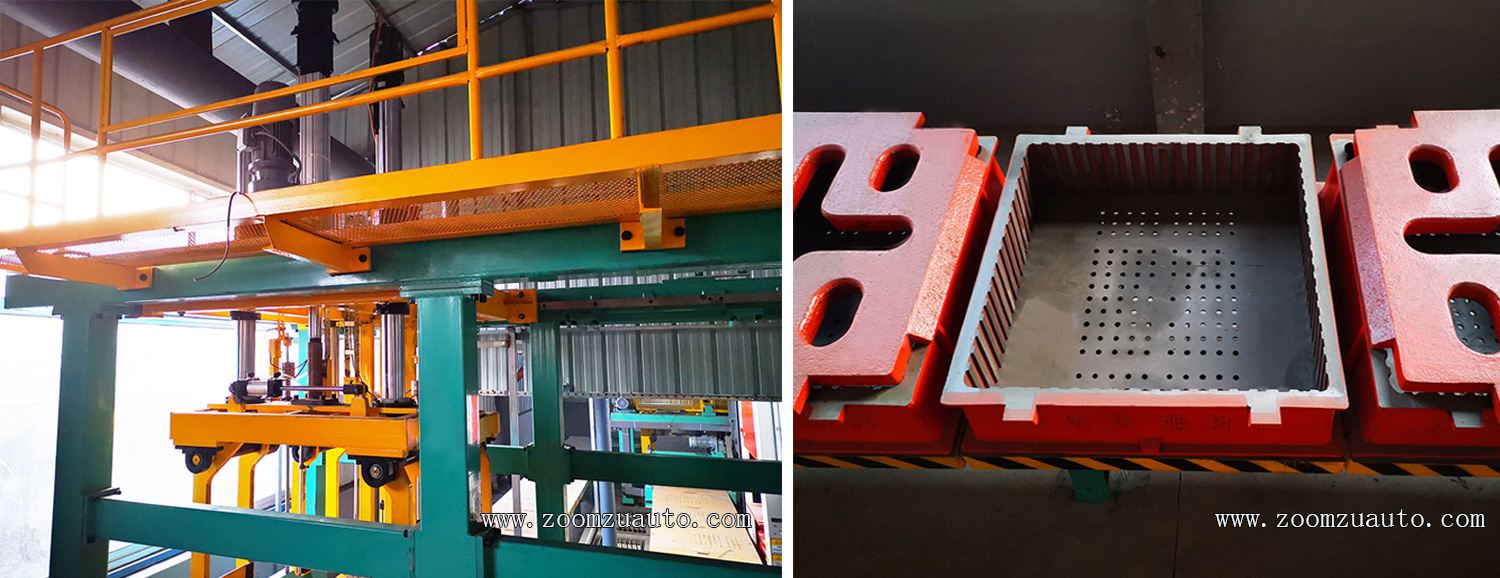

This sand box size molding machine is equipped with an automatic mixing equipment for wet sand with a processing capacity of 40T per hour. In the original casting workshop, the location where the wet sand mixing equipment is placed has been locally raised to a height of 15 meters and sufficient maintenance space has been reserved. Users can also purchase 85T non-standard steel at their location for the load-bearing and fixing of the wet sand mixing equipment, To some extent, it has reduced the production cost of the set of tidal sand mixing equipment; The above image shows the suction pipeline and mixing unit of the automated tidal sand treatment system;

The automatic molding effect of tidal sand in a 750mm X 750mm size sand box, used for the automatic molding and demolding of flywheel castings and diesel engine accessories made of ductile iron material, and the effect of the sand mold cavity after demolding;