-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

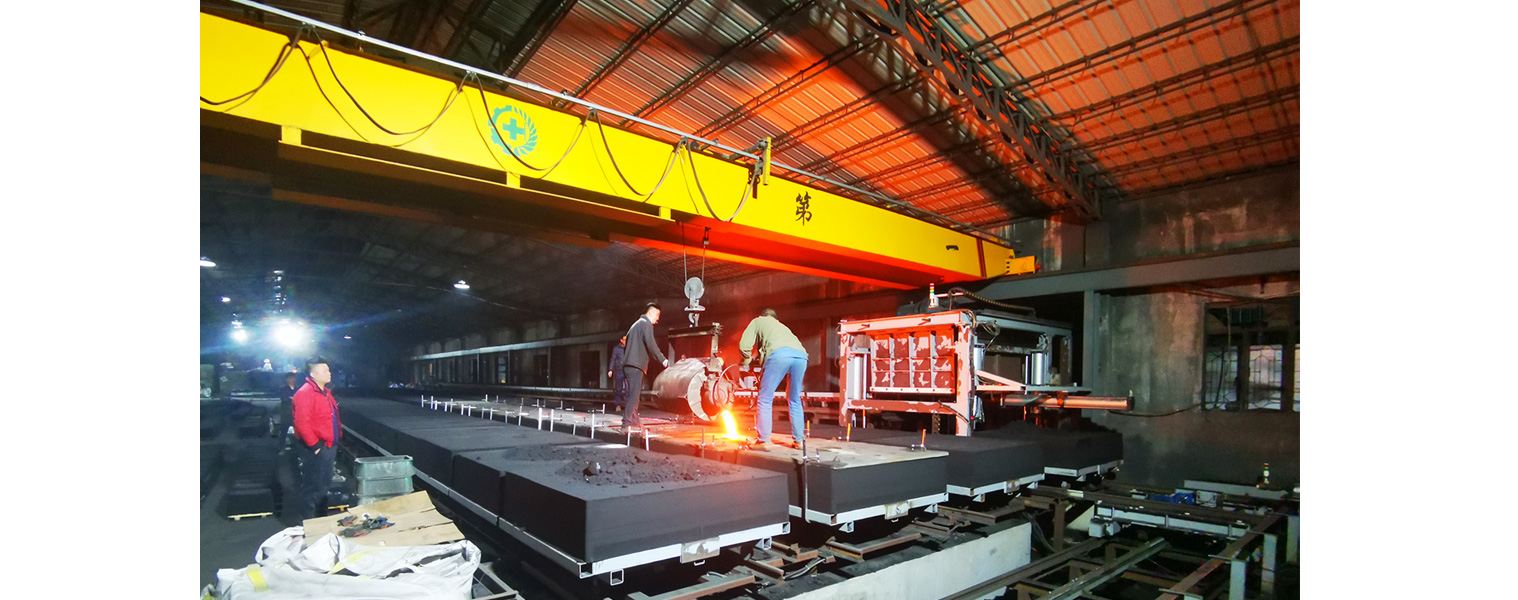

In May 2022, we will provide an automated sand casting molding machine with the size of 1620mm X 1400mm sandbox for a Chinese supplier of piano framework cast iron plate. This casting enterprise mainly provides the Pearl River piano with the production and casting of piano cast iron framework castings. The use of automated parting molding machine to produce cast piano framework will largely solve users' concerns about enterprise development. The general problem is the aging of foundry workers, The low production efficiency and increasing casting costs make it difficult to control quality issues such as smoothness and weight of castings, as well as the inability to deliver castings on time when the order volume of castings increases; Therefore, after understanding the user's issues and reaching a common solution through negotiation, we have provided them with customized automatic molding machines and supporting equipment that can meet the production needs of all casting sizes. The 1620mm X 1400mm sand box size automatic molding machine is also the largest fully automatic horizontal parting box less molding machine in Zoomzu and even the world up to now;

The piano frame cast iron plate has very high requirements for surface smoothness of castings. We have selected a 30 ton standard automated sand treatment system for mixing clay sand, providing high-quality casting sand for the fully automatic horizontal parting molding machine, ensuring the production of high-quality castings and the yield of castings to the greatest extent possible;

In the selection of automatic molding machine models, we adopted a double-sided sandblasting method and designed and manufactured steel double-sided molds. After obtaining sufficient compaction, the sand mold parting surface also obtained uniform and very good compactness. We also designed a suitable pouring system based on the manual pouring method of the casting enterprise. Overall, this was a very successful and satisfactory attempt, This is also a significant breakthrough for us in the field of automatic horizontal parting box less molding machine technology;

In terms of the selection of pouring lines, we have equipped the casting enterprise with a rail car transportation pouring production line. The main reason is that the originally installed electric furnace in the pouring workshop has a small melting capacity and the normal pouring time is mainly concentrated on uniformly pouring the sand mold after midnight;

The piano frame cast iron plate produced using a fully automatic molding machine has good surface smoothness, high dimensional accuracy, small weight error, high casting yield, good processing performance, beautiful castings, low production cost, and high production efficiency.