-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

In January 2021, we provided a conventional fully automatic horizontal parting molding machine with an automated pouring line for a casting enterprise in Shandong Province, China - Shandong Xuguang Derui High tech Materials Co., Ltd. - to increase casting capacity and expand the casting industry. The company has a 30-year development history, mainly focusing on the production, production, and sales of casting materials and casting; The casting workshop is equipped with four sets of 3-ton electric furnaces from the United States, two sets of 1.5-ton electric furnaces, four iron mold sand casting production lines, two clay sand casting production lines, and one resin sand casting production line. It also has quality testing equipment such as carbon and sulfur analyzers, direct reading spectrometers, metallographic analyzers, thermal analyzers, and tensile testing machines. The annual casting production capacity is 62000 tons, mainly producing high-end robot parts and compressor parts Automotive and agricultural equipment components.

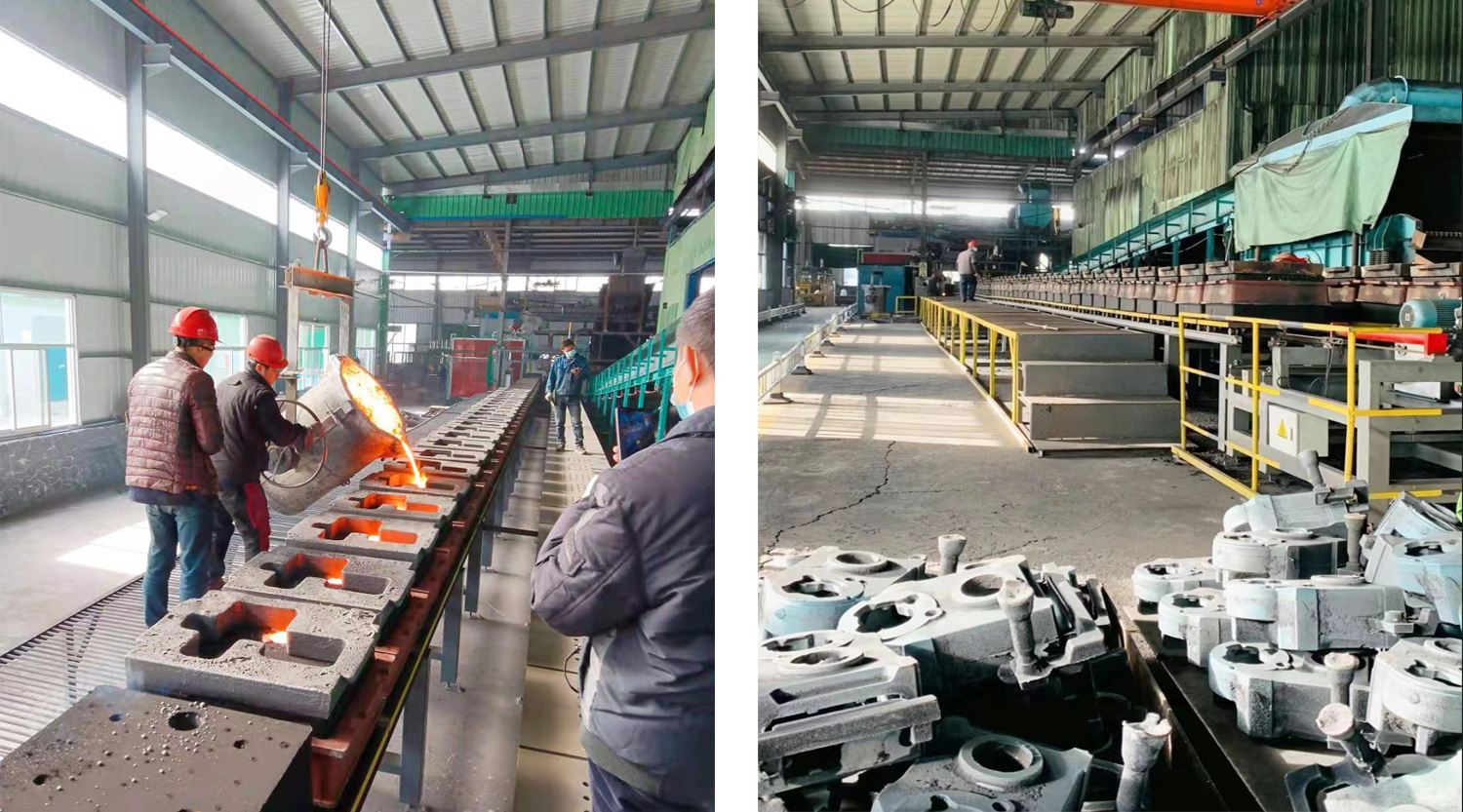

We have customized a conventional fully automatic horizontal parting molding machine and an automated horizontal pouring line for sand molds on the left according to the user's casting workshop. We have added molding sand to the original automated sand treatment system in the casting workshop to provide casting sand for the molding machine. The user has also made a heavy iron and cast iron sand mold box frame for the horizontal pouring line based on the drawings we provided. The entire line is 43 meters long and equipped with 117 sand mold cars, with 52 pouring stations, The tail is equipped with a high-temperature resistant sand mold cooling conveyor belt, with a cooling time controlled at around 45-55 minutes; This casting molding production line can produce 12T-18T cast iron parts every day, mainly producing cast iron air compressor casings, transmission boxes, and automotive gearbox casings;

The shaping effect of the gearbox shell after compaction and demolding is achieved through a horizontal automatic molding machine, and a coated sand core is placed inside the mold cavity

After the equipment installation is completed, the first pouring of ductile iron material into the sand mold is carried out manually by workers through the hanging pouring package in the casting workshop. Reasonable pouring design and timely exhaust of the sand mold ensure reliable mass production of castings;