-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

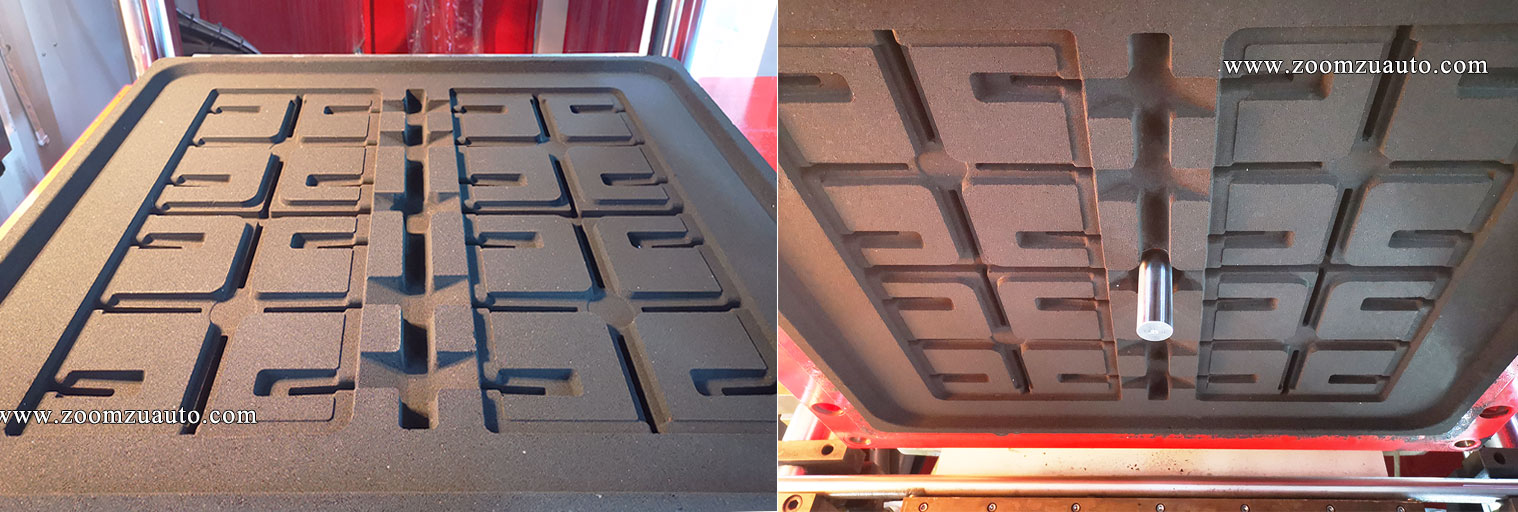

The cast iron furnace frame is produced using a conventional horizontal parting fully automatic casting molding machine, with a sand box size of 710mm x 610mm. Two cast iron furnace frame castings are placed in each sand mold cavity, and the metal iron liquid pouring port of the sand mold is placed in the middle of the sand mold. At the same time, two exhaust ports are discharged on both sides of the pouring port for sand mold exhaust and casting shrinkage during the pouring process. The structure of this casting is relatively thin, and attention should be paid to the pouring speed of the metal iron liquid when pouring the sand mold.