-

-

Guangzhou Zhongzhu Machinery Co. LtdSand casting molding machine manufacturer

-

008613926238353 WhatsApp:

-

E-mail: 470199755@qq.com

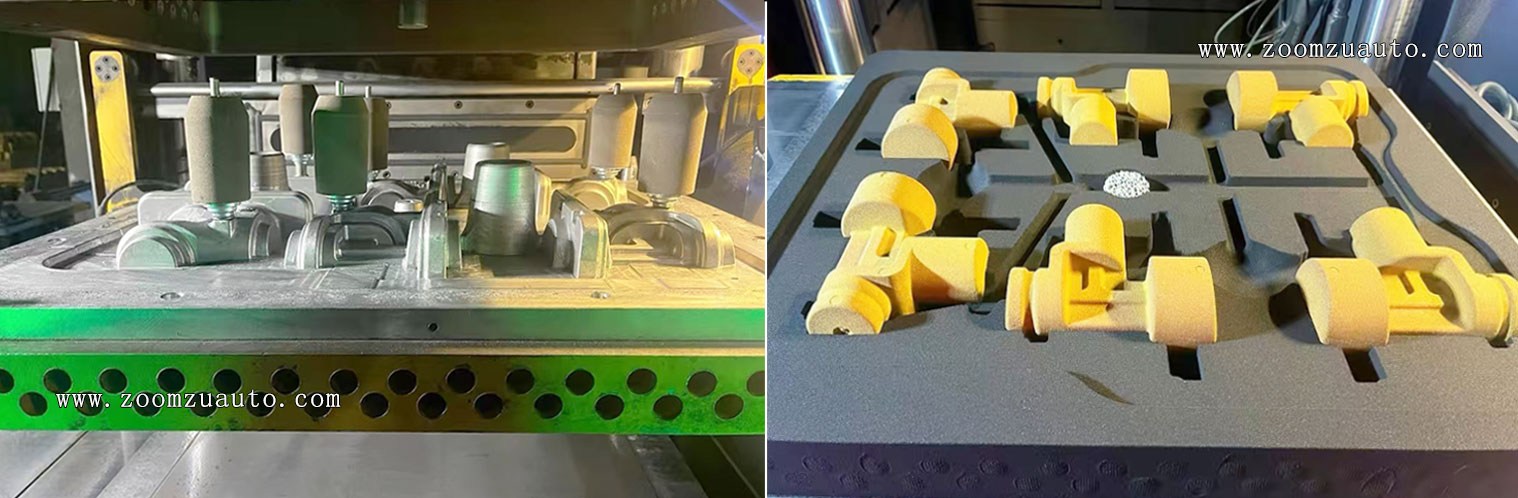

In all types of our molding machines, the molding method adopts the design principle of air flow sand addition and hydraulic compaction. In addition to the conventional sand box size model molding machine, we can also customize molding machines with other sand box sizes (length and width) and sand box heights (height of sand mold) according to the user's casting molding requirements, which need to be confirmed to be feasible and meet the requirements of casting pouring. For customized non-standard casting molding machines of this type, the production cycle is relatively long, usually taking 60-75 days; The production cycle of conventional size casting molding machines is 30-50 days;

2) The appearance colors of casting molding machines, automated pouring lines, and automated sand processing equipment can be selected and matched according to the culture and user needs of different regions;

3) For the electrical and hydraulic components of the casting molding machine, different brands of electrical components can be selected based on the user's usage needs, such as whether certain components are convenient to purchase in the user's area, whether the original brand covers the service in that area, and related after-sales maintenance;

4) For the electronic display screens of all devices, specific languages can be selected based on the user's country or region;

5) Users can provide drawings of product castings, and we will develop and produce the necessary molds and technical support for the relevant models of molding machines. These molds can also be used for sand mold molding testing and casting of finished castings;